Products & Solutions

Dry Grinding

We are your first choice for the grinding of dry products!

From A (activated carbon) to Z (zinc oxide) -

we offer the right mill for your product.

Our extensive experience and wide range of mills are available for the fine cutting, fine grinding and ultra-fine grinding of dry products of all desired finenesses.

High-performance classifiers for the finest of products, round off our program.

From individual mills to complete turnkey milling systems; non-PSR or dust explosion protected plants up to 10 BAR PSR (pressure shock resistant) and inert gas plants are available; material executions in a diversity of designs including stainless steel with polished surfaces or wear protected models - We have the perfect solution for you!

NETZSCH Dry Grinding Solutions

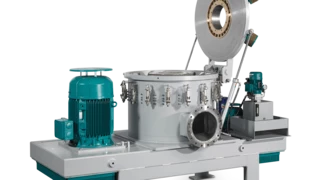

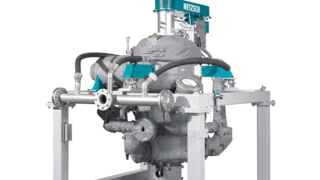

Impact Mills

In general, rotary impact mills are used for the grinding of soft products to products with medium-hardness (up to hardness 3 on Mohs scale) with a fineness of several mm down to a one-digit µm-range. These mills are equipped with a rapidly-running rotor with suitable grinding tools around which grinding tracks, screens or counter-rotating pins are used as an impact partner.

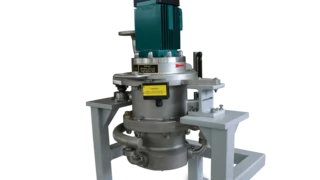

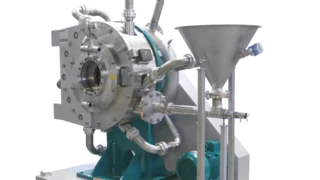

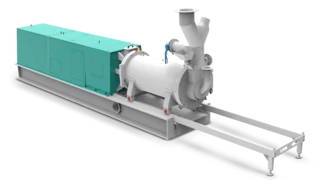

Jet Mills

In jet mills the size-reduction of particles is carried out in a gas jet. The grinding gas (air or argon) is guided into the grinding chamber and accelerated in such a way, that product particles are carried along in the gas flow and impact against each other. Size-reduction is autogenous and contamination is therefore low. Jet mills are predestined for grinding dry- and very hard materials to obtain a particle fineness in a range of 0.1 µm to 100 µm.

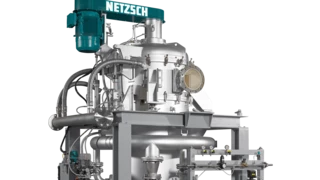

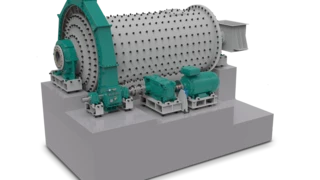

Bead Mills

There are numerous application areas which demand a high fineness at high throughput capacities with a low energy consumption, especially in the area of dry grinding. For this reason, it was important for NETZSCH to transfer the globally tried and tested agitator bead mill technology to dry-grinding and to complement the triumph of the IsaMill in wet-grinding in the mining sector with the dry agitator bead mill.

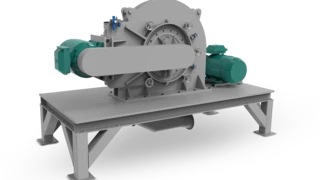

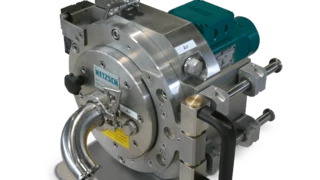

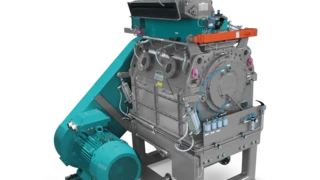

Cutting Mills

Cutting mills are used to grind and homogenize medium-hard to soft and elastic materials. In this process the material is ground by shearing forces using rotary- and stator knives. As a rule, the material is fed into the machine from above, it falls onto the rotor and is ground between rotor- and fixed cutting knives.

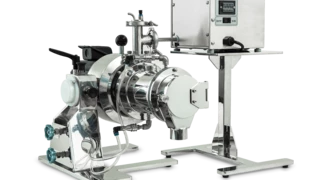

Laboratory Plants

NETZSCH laboratory plants are setting new benchmarks as regards operating convenience, compactness and flexibility. Depending on the application, these plants are rounded off with fluidized bed jet mills, high density bed jet mills, classifier mills and impact mills, as well as fine-classifiers and high-performance fine classifier.