Energy Solutions

Anode and Cathode Materials

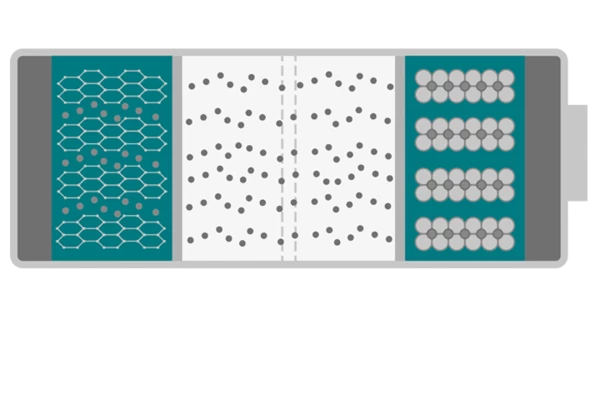

One option for the synthesis of cathode and anode materials is the so-called solid-state process. In this process route, the active material is created from the raw materials through a chemical transformation in suitable furnaces. Depending on the raw materials used, a wet grinding stage with dry pre-grinding processes can be required for the raw materials prior to the synthesis.

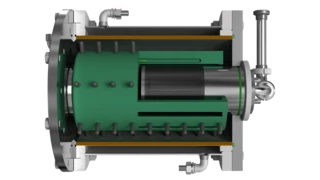

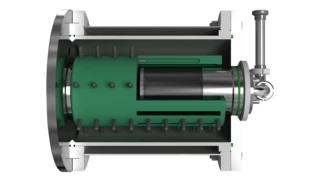

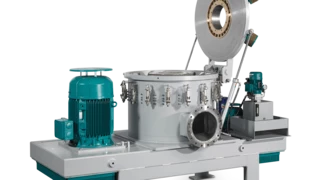

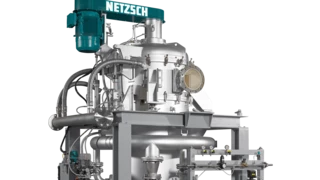

The CGS and s-Jet® fluidized bed jet mills can be used for the dry grinding. For the wet grinding, the Zeta®, Neos or Zeta®RSagitator bead mills are used, depending on the required target fineness. Synthesis via a furnace process can result in the formation of undesired agglomerates. In order to separate these, a dry dispersion with a CSM classifier mill is usually carried out after the synthesis furnace, without change of the original size and shape of primary particles.

Typical compounds for cathode materials are:

- LCO (Lithium Cobalt Oxide, LiCoO2)

- NCA (Lithium Nickel Cobalt Aluminum Oxide, LiNiCoAlO2)

- NMC (Lithium Nickel Manganese Cobalt Oxide, Li[NiCoMn]O2)

- LMO (Lithium Manganese Oxide, LiMn2O4)

- LFP (Lithium Iron Phosphate, LiFePO4)

- The conductor foil is usually made of aluminum

Some examples of active materials for anodes are:

- Amorphous Carbon

- Graphite

- Lithium Titanate (LTO, Li4Ti5O12)

- Metallic Anode Materials (Silicon, Tin)

- The conductor foil is usually made of copper.