Process Technology for the Rounding of Graphite

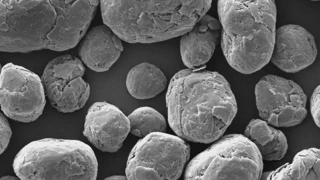

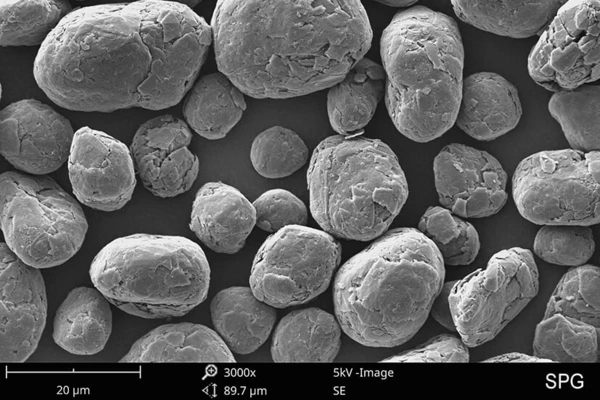

Ideally, spherical graphite is required for the production of the anodes of lithium-ion batteries.

Natural graphite and synthetically produced graphite are platelet-shaped and show a characteristic layer structure. The goal of further process steps, including comminution, is therefore to achieve a rounded product with a narrow particle size distribution as well as high tap density and yield.

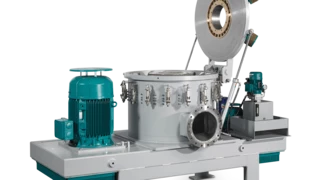

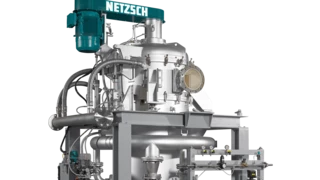

The NETZSCH Process – GyRho Rounding Unit

The graphite rounding process developed by NETZSCH overcomes disadvantages of the previously widespread used process requiring more than 20 classifier mills installed in rows: In a first step, the flock graphite is pre-ground to the optimum initial particle size for spheroidization in a classifier mill or fluidized bed jet mill.

The actual particle rounding process takes place directly downstream in the newly designed NETZSCH GyRho Rounding Unit (Fig. 2) which is available in various construction sizes and can be specially designed to suit the necessary output quantity. For larger throughput volumes two (or more) machines can be operated simultaneously and can replace the train of 20 machines or more as mentioned above.

The efficient spheroidization process in the GyRho is divided into three phases: Filling, Rounding and Discharging. During the filling phase, the maximum product volume is conveyed into the process chamber. In the rounding phase, the particles are stressed to the point of rounding by optimum geometry and process parameters, and in the final step, the emptying phase, the process chamber is emptied by suction with a cyclone and the product is separated.

By optimizing the design of the grinding chamber and reducing the number of components, it was possible to increase yields of 30 to 40% achieved by the standard system to 60 to 65% with the GyRho. At the same time, using specific settings, it is possible to achieve the maximum yield of final product with the desired quality. Quality criteria such as distribution width, tap density and particle size can be influenced by varying the process parameters. In this way, using the GyRho system, all qualities required by the market, such as spherical graphite with a tap density of more than 960 g/l at a d50 value of 16.8 µm and a yield based on a raw material volume of > 60% are achievable.

Request Product

Your Benefits

Plant data for the NETZSCH GyRho System compared to competitors´ systems

30 % higher plant availability

65 % total yield*

* up to 65 % total yield based on amount of raw material and depending on its origin and type

35 % lower operating costs*

* Opportunity-, working-, spare part-, electricity costs, depreciation and costs for graphite concentrate

90 % lower maintenance costs

60 % smaller surfaces

60 % less energy

Videos

Application Literature

Your Contact at NETZSCH

Any specific questions? Contact us for help.

you may also be interested in: