Products & Solutions

NETZSCH-Beads® Grinding Media

Always the Right Choice

The grinding media, also referred to as grinding balls or grinding beads, serve as the tools in mills with freely moving grinding media, such as agitator ball mills.

The movement of these grinding balls within the mill generates various stresses between the balls and the product, including impact, pressure, friction, and shear.

These interactions enable a range of processes. Depending on the particular product and task at hand, these could include size reduction, dispersion, or deagglomeration processes, as well as emulsification, cell disruption, or homogenization.

As the tools of the ball mill, the media have a crucial impact on the outcome of the dispersion or wet grinding process. Therefore, the selection of suitable media represents a key optimization feature. Used media should be matched to the characteristics of the raw materials, the objectives of the process, as well as the milling technology employed.

We assist you in selecting the right grinding media, ensuring that with the use of NETZSCH-Beads®, you achieve optimal results in terms of energy efficiency, production output, wear and maintenance cost, operational reliability, and sustainability.

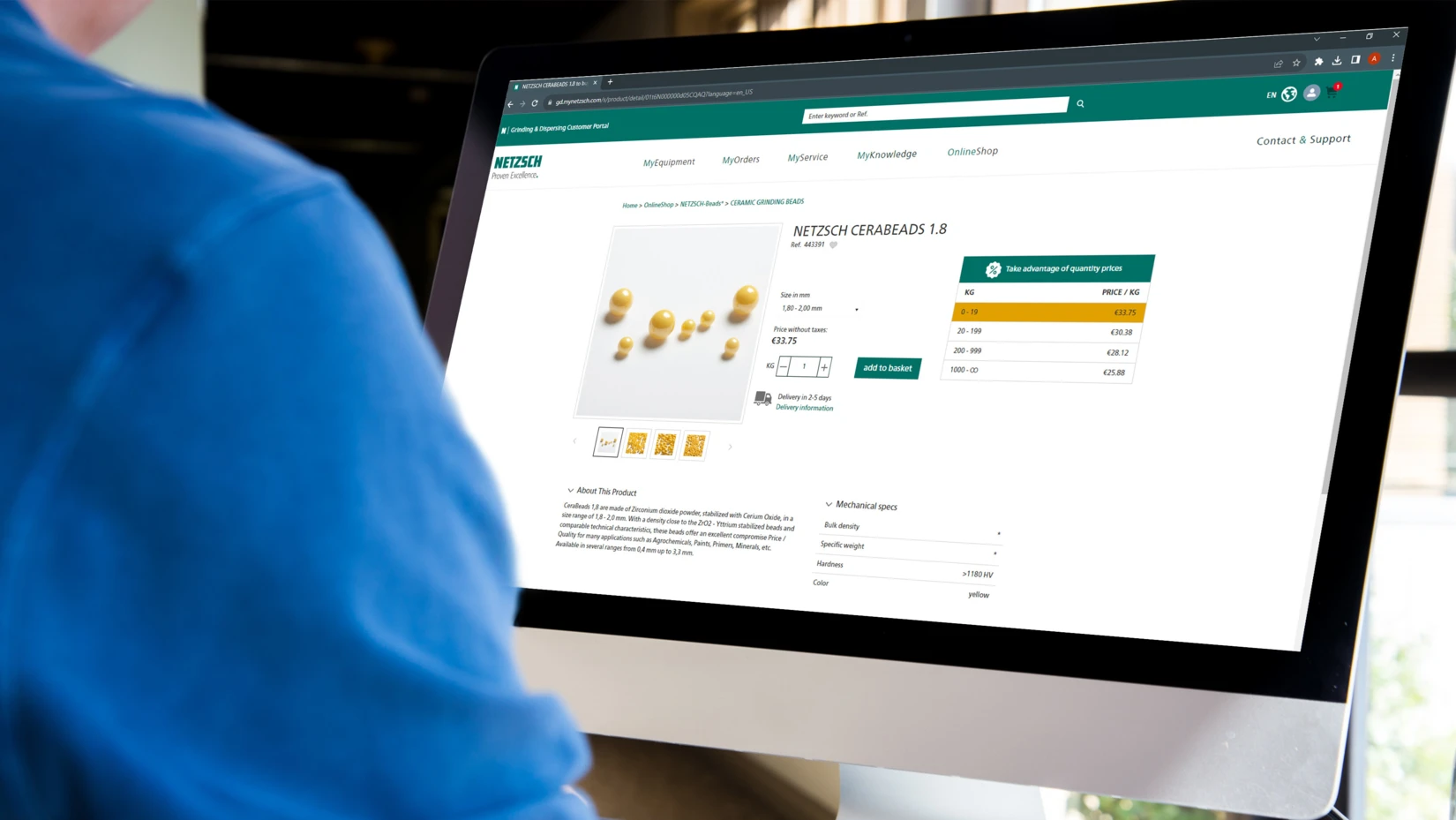

Access to the Customer Portal

Experience the advantages of NETZSCH-Beads®:

- Ideally adapted to your raw material properties, your objectives, and your milling technology

- Consistently high quality of grinding media

- All essential types of grinding media available in various sizes

- Grinding balls and milling technology from a single source

- Potential improvement of your product quality

- Process optimization and increased production output

- Enhanced energy efficiency and operational safety

- Reduction of maintenance effort

- Worldwide NETZSCH service

Our Special Service for you

In our application laboratories, we can jointly conduct tests to both make an optimal selection of grinding media for your specific requirements and to determine the efficient grinding system and the ideal operational parameters of the agitator bead mill.

The tests can be performed on a laboratory scale as well in the pilot plant. We cordially invite you to accompany the tests in our premises and to be in close exchange with our application specialists.

Grinding media in the mill, depending on the properties of the processed products and the stress conditions, are subject to wear to a certain degree. For an efficient and optimal operation of your agitator bead mill, you should check the diameter and shape of your NETZSCH-Beads® at regular intervals. Similarly, the mill's grinding media filling level should be maintained at a constant level. If the grinding balls fall below a certain diameter due to wear, or if the fraction width of the balls becomes too wide, issues can arise in the mill's production process. These can manifest as screen blockages. It may also be the case that the desired product quality can no longer be achieved within the usual operating time, or not at all.

To ensure a smooth production process, there is the option to sieve out balls that are no longer within the specification and to replace the missing quantity with NETZSCH-Beads®. We are happy to advise you!

Boosting production efficiency with NETZSCH-Beads®

By using the optimal type of grinding balls, you can achieve the highest level of energy efficiency, thereby increasing the production output of your agitator bead mill. In selecting the grinding media, we consider not only the density, material composition, surface quality, and diameter of the grinding balls, but also the properties of your products, the grinding system, the circumferential speed of the agitator shaft, and the required energy input. Should you have any further questions, our experts will be happy to help you.

FAQ - What you should know

Your Service Contact at NETZSCH

Any specific questions? Contact us for help.