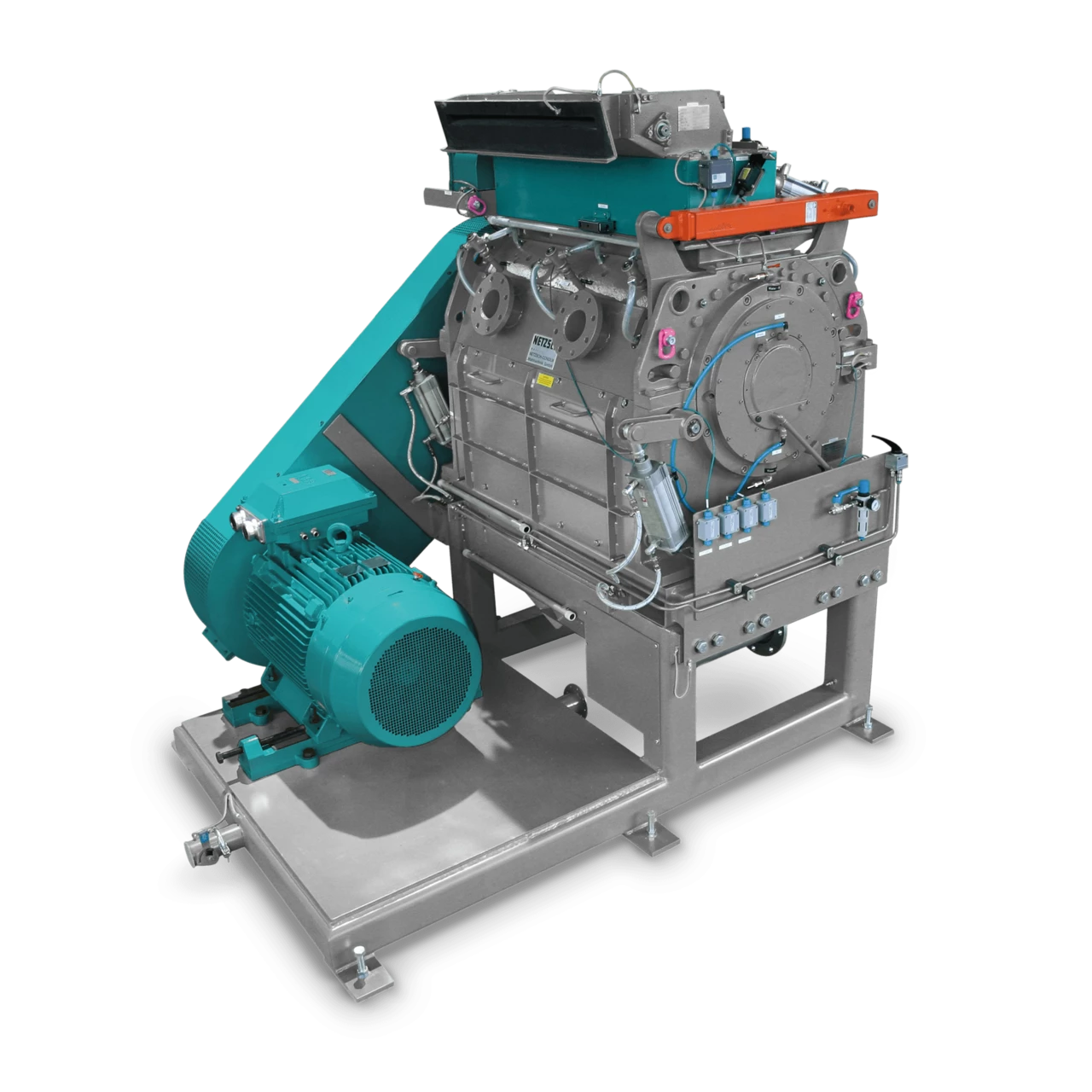

The fine cutting mill CS-Z for the size reduction of non-friable and soft products.

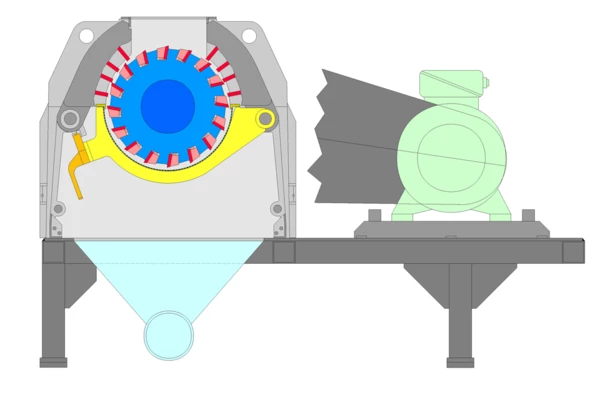

By maximizing the cutting strokes (rotational speed of the rotor x number of rotor knives x number of stator knives) and the use of special screen inserts, highest finenesses can be achieved with this multi-knife cutting mill. The open rotor design increases the air flow, the results of which are a high throughput capacity, good powder quality and the highest bulk density.

Due to the central position of the feed inlet, product can be fed without danger of overloading!

Continuous feeding of rolled product is possible when specially designed feeding systems are mounted on top of the machine inlet.

Request Product

Technique

- Finenesses from 0.1 to 3 mm

- Multi-knife cutting mill for the fine cutting of non-friable and soft products

- Fineness adjustment through a wide selection of screen perforations

- Variable number of knives

- Bearing of the rotor shaft in heavy roller bearing with continuous heat exhaust through water-cooled flange bearing shields

- Particle contamination of the bearing housing is prevented by air rinsing of the bearing seal to the cutting chamber of the machine

- High rotational speed of the cutting rotors

- Effective cooling of product directly on the cutting surfaces

- Energy saving due to real shear cut

- High cutting capacity through maximized cutting strokes

- Extreme stability due to robust design

- Fast knife changes made possible by easy, exact rotor knife adjustment

- Fast, easy screen changes without tools

- Water cooled housing designs available

- Pressure shock resistant designs also available

Your Contact at NETZSCH

Any specific questions? Contact us for help.

you may also be interested in: