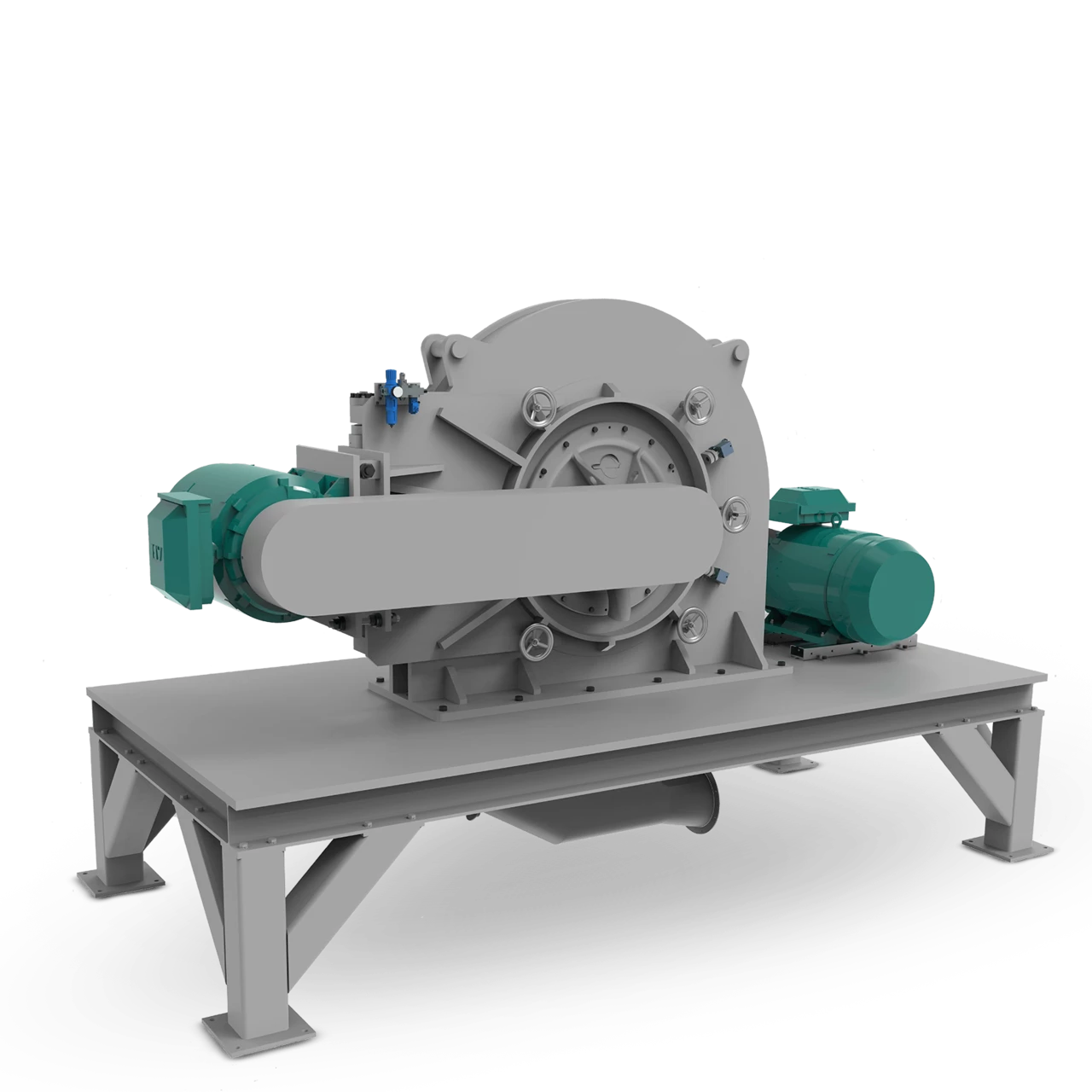

With contra-rotating pin discs, the resultant tip speed is over 200 m/s, which enables the grinding of soft to medium and hard minerals to its highest fineness. Independent control of the speed and direction of rotation of the pin disc drives give a high degree of flexibility. An airflow through the mill assists the grinding, enables the control of product temperature and provides a medium for pneumatic transfer of the product.

As standard, the mill body is a robust, welded mild steel construction. Access on the Sierra mill is excellent and pin replacement is an easy operation procedure. The Sierra mill also represents an economical and highly efficient method of coating ultra-fine fillers with stearic acid.

Focus on Your Advantages

Request Product

Downloads

Your Contact at NETZSCH

Any specific questions? Contact us for help.