Products & Solutions

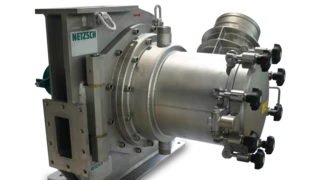

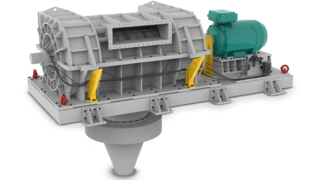

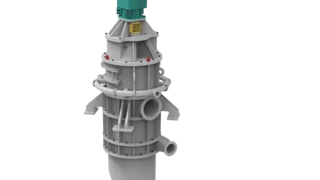

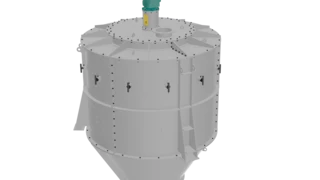

Air classifying of dry powders

Due to their particle size distribution, some processed products still do not meet application requirements. Fine fractions or oversized particles interfere with further processing or make the final product unsuitable for the targeted application.

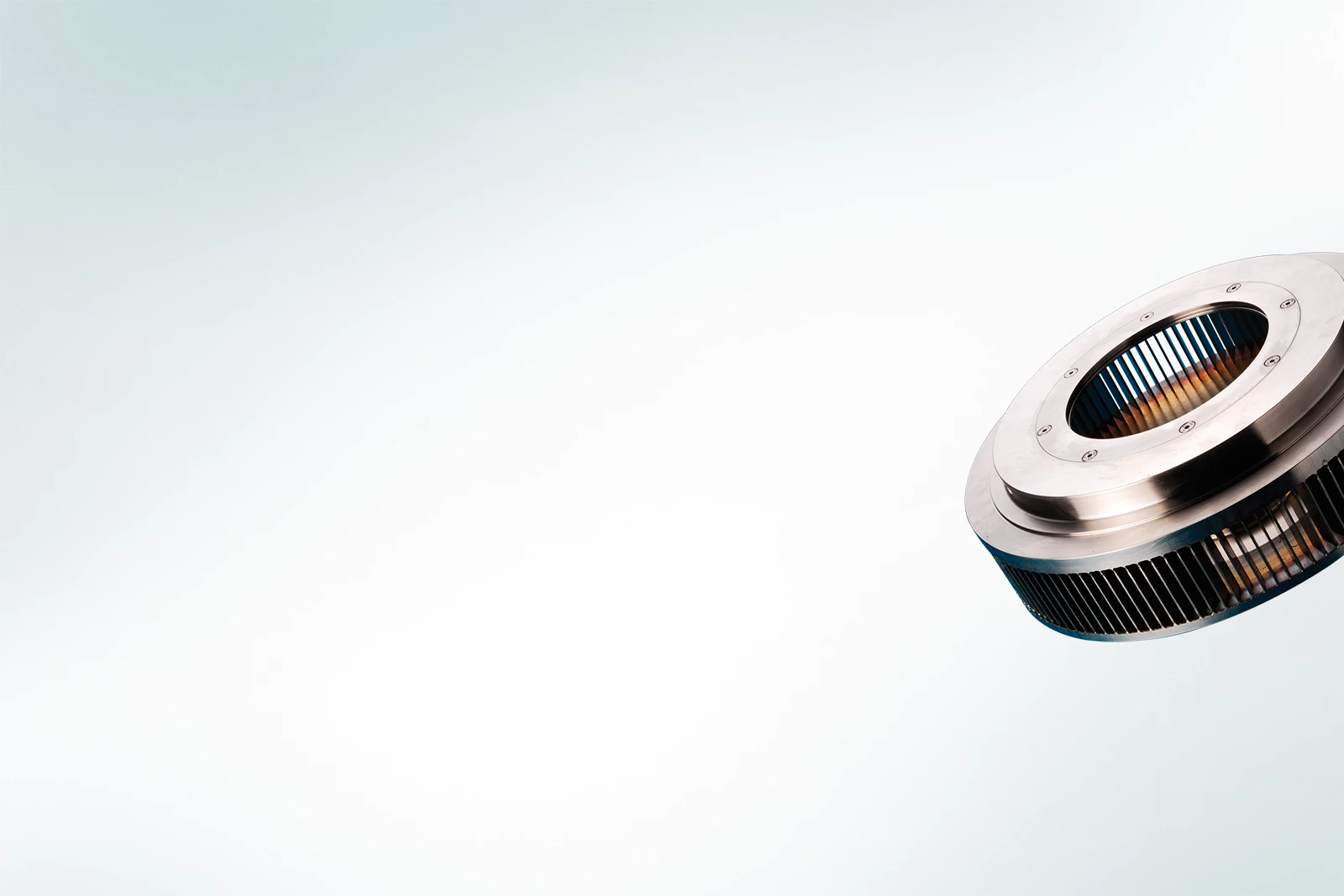

Such products require additional "optimisation" to meet the desired particle size distribution necessary to improve the product's characteristics. Customarily products with a particle size range of >100 µm can be classified without difficulty using a screening machine, however, air classifiers are essential for finer particle size distributions that require a more controlled separation.

Typical applications for our fine classifiers are the separation of undesired coarse grains and the distinct reduction of fines (de-dusting).

Different machine designs are available, depending on the desired cut points or application. Machine sizes are available for nearly all ranges of capacity. We carry out the project planning, production and commissioning of individual machines as well as complete classifying plants.