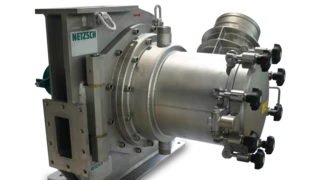

The new s-Jet® 25 is a small and compact laboratory unit and the logical complement to the proven new steam jet mill s-Jet® series.

With this new development, it is now possible to manufacture nano-particles on a laboratory-scale with dry-grinding.

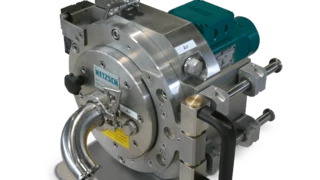

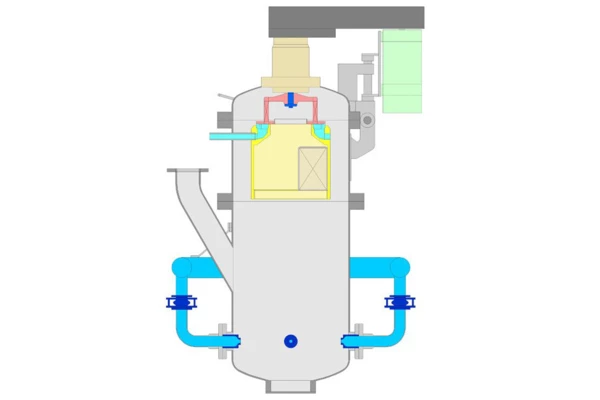

This System is a combination of spiral jet mill and integrated dynamic air classifier. High finenesses can be obtained with this mill, independent of the load in the air jets. During the development of this plant great care was taken to create a system especially suitable for manufacture of very small amounts and product sample.

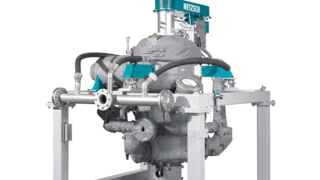

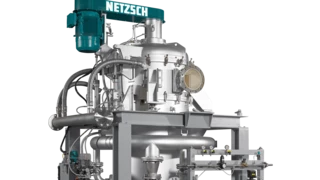

The compactly constructed lab-plant includes all necessary components such as dosing, mill, product separation, control unit, fittings and steam generator on a skid. The space required for the assembly of the complete steam grinding plant is only 3 m2, while the maximum necessary height is 2450 mm. All product-contacted parts as well as the assembly frame made of stainless steel. The plant is delivered completely mounted and ready-for-operation. Central connection points for compresses air and electricity, water inlet and-outlet ensure very short installation- and commissioning times. Further requirements were an ergonomic design and easy cleaning, as well as condensation of the waste steam vapors produced during this process. This allows a flexible assembly of the system.

An integrated dynamic air classifier in the housing can be infinitely adjusted to the desired fineness. This guarantees exact adjustment of the grinding parameters and reproducible product quality.

Even the hardest of products poses no problem for this steam mill. In addition, moist products can be ground and dried simultaneously using superheated steam without any additional pre-drying process for inlet.

The new s-Jet® System (steam, superfine)

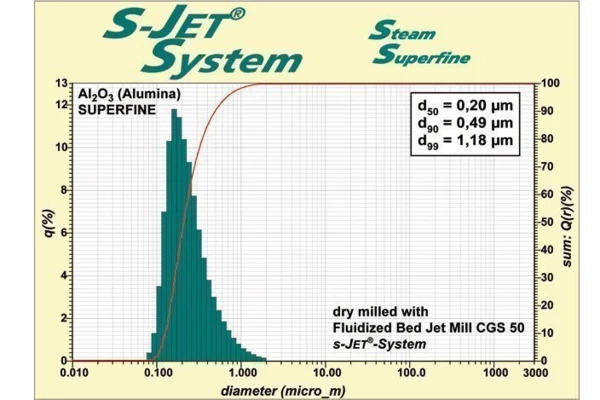

The increasing interest in finer, dry products has led to the development of economical dry-grinding processes down to the submicron range. The new s-Jet® System (patent pending) is a innovation in a line of consistent developments being made in the area of air jet milling. Final finenesses in the submicron range (example: d50 0.2 µm) can now be achieved by steam jet mill, which was only possible by means of wet media milling process at the past.

As opposed to conventional dry grinding processes with fluidized bed jet mills, the s-Jet® System uses superheated steam as its milling gas.

Compared to air, steam provides considerably higher jet energy. Jet speeds of up to 1,200 m/s can be achieved ( Air about 550 m/s ) and the kinetic impact energy of the particles inside the fluid bed rises fourfold! This allows achieving finer particles in dry–grinding process as opposed to air operations. The higher total energy input leads to a distinctive increase in throughput (more than double the capacity!). Therefore, the throughput of a machine can be increased immensely, without changing the fineness.

Since steam moves at a higher speed of sound than air, the circumferential speed of the current inside the classifier wheel can rise, which in turn influences the acceleration forces effecting the material being classified. This is the decisive step toward classifying particles into the submicron range for the first time, via dry grinding.

Request Product

Technique

- Highest grinding fineness < 150 nm (d50) dry grinding

- Development of new products & applications

- Processing of sticky products

- Optimal product performance

- Highest product purity

- Steep particle size distribution

- Small sample amount possible

- Variable assembly possibilities

- Small amount of space required

- Ergonomic design

- Easy cleaning

- Simultaneous grinding and drying of moist products

- Using superheated steam for the ultra-fine grinding of soft to hard

- Exactly defined maximum particle size through integrated dynamic air classifier

- Reproducible results

Videos

Downloads

- NETZSCH Steam Jet Mill s-Jet®Brochure

- NETZSCH Laboratory Plants - Ultra-fine Grinding and Ultra-fine ClassifyingBrochure

- Putting the (steam) pressure on dry grindingTechnical article

- Nanonization: A New Word for an New ProcessTechnical article

- Going "Green" using SteamTechnical article

- Steam is powerTechnical article

Your Contact at NETZSCH

Any specific questions? Contact us for help.

you may also be interested in: