business field

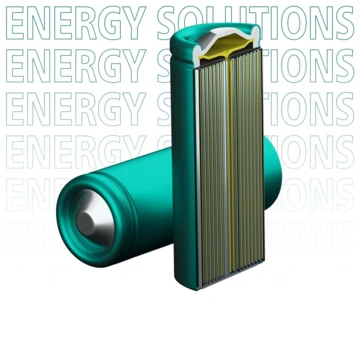

Energy Solutions

With the "Energy Solution" business field, we shape the future of tomorrow with you. Leading manufacturers trust our grinding machines and process solutions for the production of the latest batteries and accumulators.

Lithium ion batteries store and supply electrical energy in mobile telephones, laptops and tools. Mobile applications, such as electric bicycles, electric scooters and other electric vehicles and hybrid concepts are also creating a steadily rising demand for batteries.

The goal is to develop ever more powerful batteries that feature increased capacity, a longer lifetime, shorter charging times and lighter weight. Lithium ion batteries are basically comprised of a negative electrode (anode), a positive electrode (cathode) and a separator membrane. The individual electrodes are made up of conductor foils that are coated with a mixture of binders, active materials and additives (battery slurries).

In addition to the mechanical and thermal resistance of the separators, the key factors for the quality and safety of the batteries are the chemical composition, the shape and particle size distribution of the active materials, the homogeneity and the absence of defects in the coatings on the conductor foils of the electrodes.

Based on many years of experience, NETZSCH offers an extensive portfolio of machines and equipment for dry and wet grinding, mixing, homogenization, dispersion, delamination, separation and deaeration, as well as analysis.