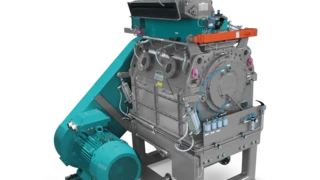

The Impact Mill Condux® is a high speed fine impact mill for the dry grinding of various products up to a Mohs hardness of 3 - 3,5.

The diversity of grinding tools allow the mill to be used universally depending on the application and area of operation. This of course also applies later on, when circumstances such as product characteristics or requirements have changed, the grinding tools can be changed as well.

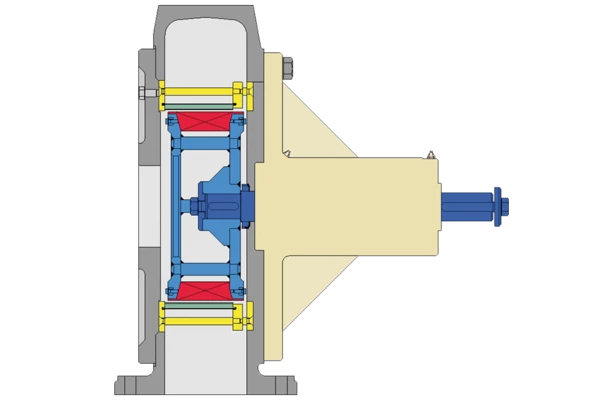

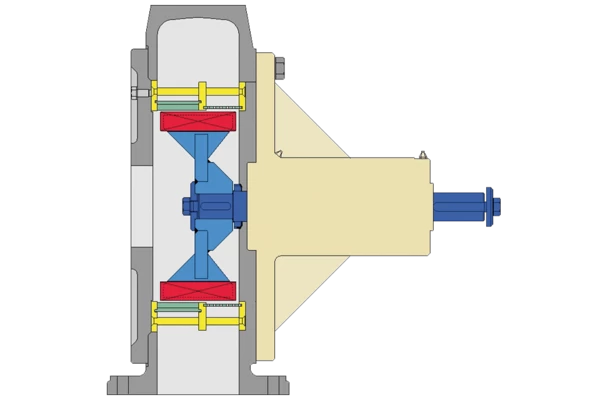

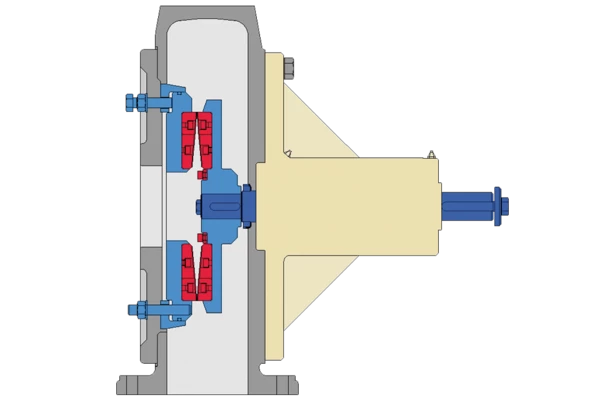

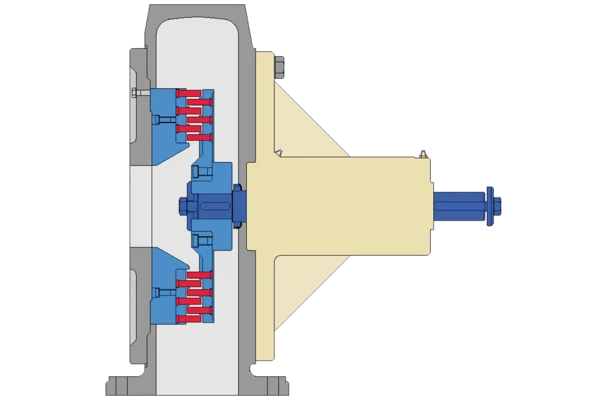

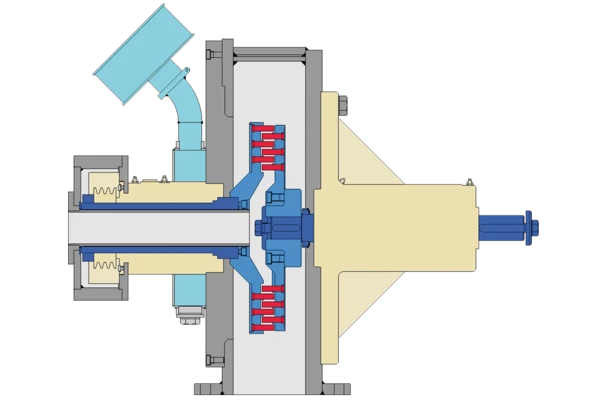

Depending on the application and product, the mill is equipped with differing rotor and stator variations and can be operated as any of the following mill types: Pin Mill, Blast Mill, Beater Mill or Attrition Disc Mill.

One design variant with 2 housing doors can be used either as a single rotor or a counter-rotating pin mill.

Impact Mill Condux® with integrated Classifier

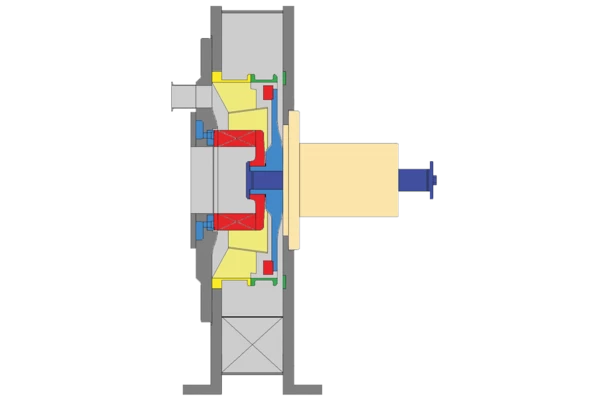

The newly designed Condux® Impact Mill with an integrated dynamic air classifier is used when the desired final fineness cannot be achieved with conventional screenless pin mills or blast mills with screen inserts. In contrast to conventional classifier mills, the grinding disc and classifier wheel are torque-proof connected to each other and are operated by a common drive motor. By adjusting the height of the classifier wheel, it is possible to achieve a variable setting of the separation limit in a simple way.

With the Condux® CP, high finenesses (< 30 µm) and exact upper particle size limitation can be achieved.

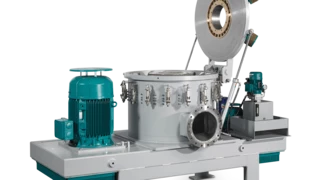

Impact mill Condux®Compact

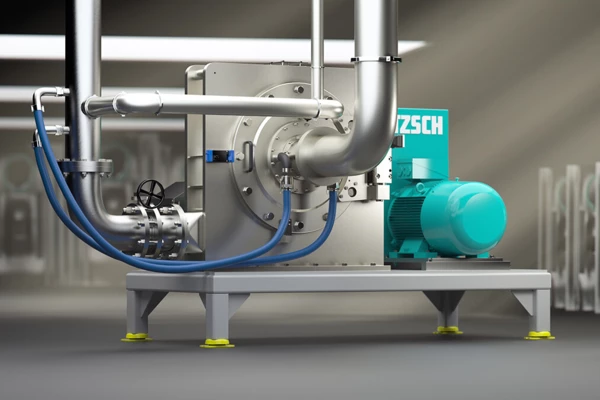

Simple Sugar Grinding – ATEX-compliant

The grinding of products, whose dusts are potentially explosive, places particularly high demands on the technology used and the design of a grinding plant with regard to safety. The most frequently used variant is a complete grinding system which is pressure shock resistant up to 10 bar (g). However, this usually means considerable costs for peripheral equipment.

With the new ATEX-compliant plant concept Condux®Compact, the installation of a more efficient grinding plant for many products is considerably easier: With this newly developed plant concept, explosion protection valves or explosion suppression equipment, explosion-decoupling devices, ventilators and even dust filter systems are no longer required in the classical sense.

Request Product

Technique

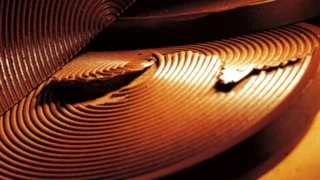

- Finenesses from d99 < 30 µm to d99 800 µm

- High speed impact mill with exchangeable grinding tools for the grinding of soft to medium hard materials (Mohs 3 – 3.5)

- Grinding takes place in a vertical Rotor/Stator-System in numerous variations:

- Beater Mill

- Blast Mill

- Pin Mill (single rotating and counter-rotating)

- Attrition Disc Mill

- Robust one-piece machine housing with hinged door provides very good access for fast and easy cleaning and maintenance

- Fineness set by adjustment of the rotational speed and tool selection

- Bearing of the rotor shaft is a grease lubricated roller bearing in a flanged bearing housing

- Optional design with 2 doors for single rotating and counter-rotating operation

- Relative circumferential speed up to 250 m sec-1 (counter-rotating operation)

- Flexible

- Fast and easy modification of the mill

- Optional designs available: pressure shock resistant, gas tight

Videos

Downloads

- NETZSCH Fine Impact Mill ConduxBrochure

- NETZSCH Impact Mill Condux CompactBrochure

- NETZSCH Impact Mill Condux 150 CompactBrochure

- Milling of SpicesBrochure

- Innovative Process for Cryogenic Grinding and Inline ScreeningCase Study

- White and Fine - The reliable and effective Milling of Icing SugarTechnical article

- More than paper - Mills and classifiers for processing celluloseTechnical article

- Universal Mill: Grinding versatility in an economical packageTechnical article

Your Contact at NETZSCH

Any specific questions? Contact us for help.

you may also be interested in: