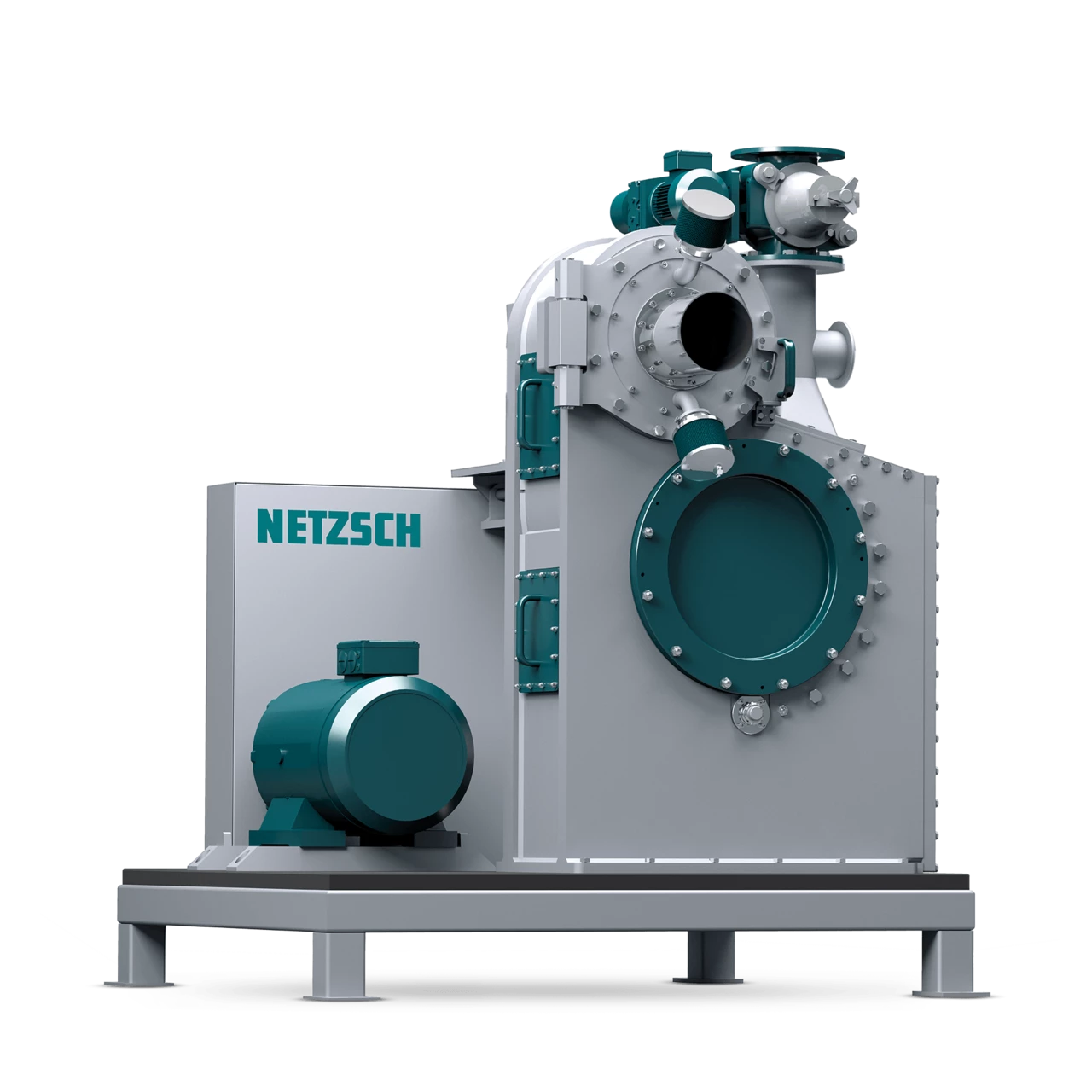

Fine Cutting Mills of the type SecoMy® S are high speed cutting mills with high-frequency cutting strokes for the fine-grinding of cuttable materials.

In contrast to classic cutting mills, final finenesses of up to 45 μm can be reached in a one-step process with the SecoMy® S. This is possible due to an air classifier integrated into the machine housing, which replaces the traditionally-used screen mesh. A dynamic classifier wheel classifies the ground product within the mill and forms the product discharge for the fine fraction.

Focus on Your Advantages

Lower energy costs

Highest flexibility

Best product quality

High yield

Low product temperatures

Highest availability

High bulk densities

Narrow particle size spectrum

Possibility of blending

Increase in productivity

One-step ultrafine grinding

Request Product

Technique

Constructional Characteristics of the SecoMy® S

- Screenless fine-cutting mill

- Thermally optimized system

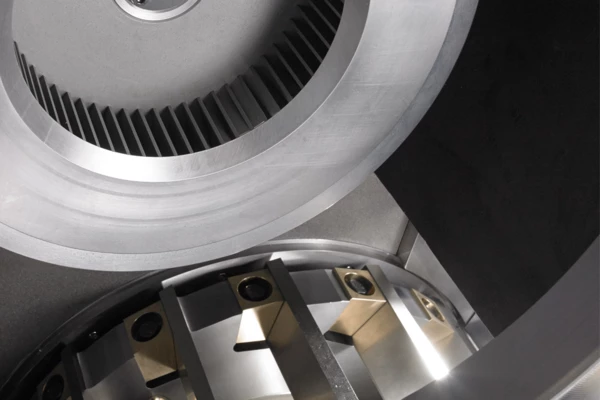

- Optimized variable knife concept

- Coolable by air and water

- Adjustable grinding air flow

- Small amount of wear parts required

- Rotary knives adjustable from outside the machine

- Very simple knife change

- Compressed air-rinsed bearing sealings to prevent product entering into the bearings

- Gap rinsing for classifier wheel to avoid oversized particles

- Wear protection possible

- Optional pressure shock resistant execution

- Optional gastight execution

- Textiles

- Mineral fibers

- Plastic fibers

- Carbon fibers

- Paper

- Plastics

- Wood

Videos

NETZSCH Fine Cutting Mill SecoMy® S

Your Contact at NETZSCH

Any specific questions? Contact us for help.

you may also be interested in: