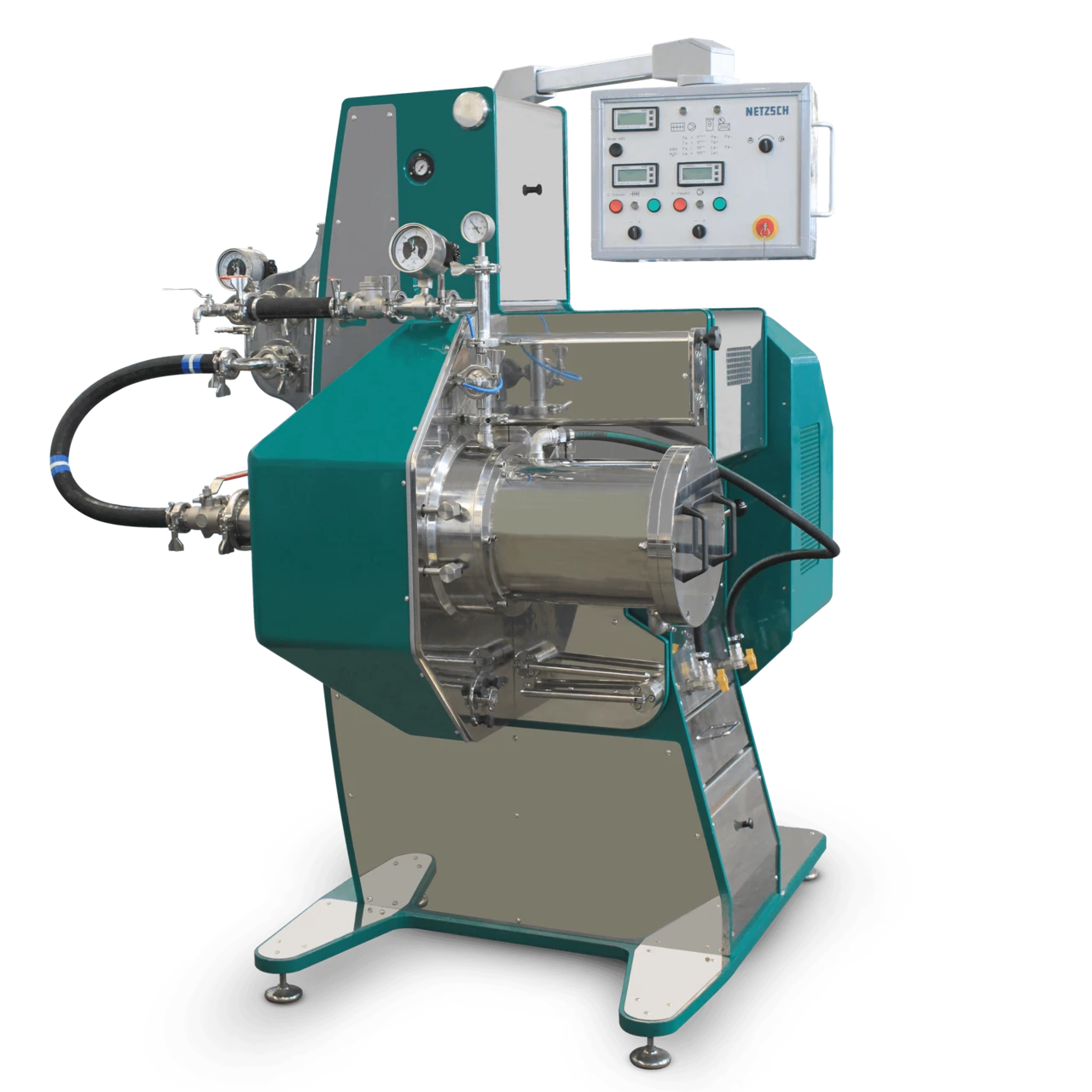

The nano mill Zeta®RS is the next development of the worldwide known circulation mill system Zeta® type LMZ. Its field of application starts where the other agitator bead mill system Zeta® ends. The highly efficient centrifugal separation system enables the use of smallest grinding media from a diameter of 30 – 300 µm in reliable continuous operation.

It is specially designed for wet grinding and dispersing processes especially "gentle dispersing" in the nanometer range. Working with the machines is a pleasure due to its easy operation.

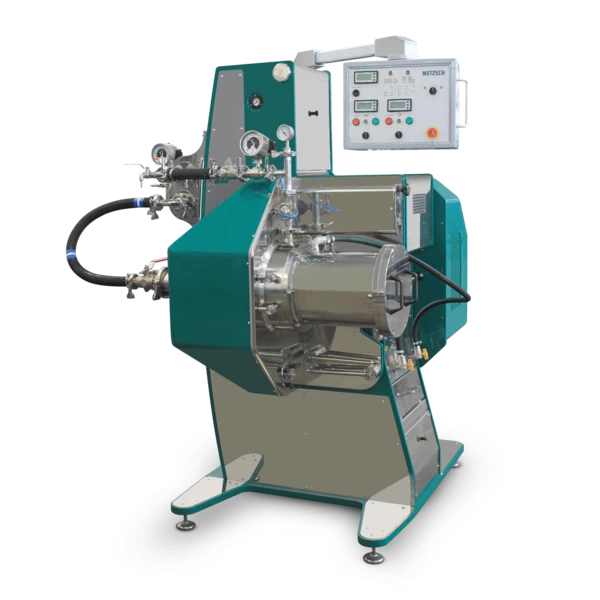

The agitator bead mill Zeta®RS is equipped with a swiveling grinding unit and lifting device with multiple positions for easy emptying, filling and cleaning and a horizontal working position.

Focus on Your Advantages

- Compact design for minimum space requirement

- Easy handling with swiveling grinding unit and sliding grinding tank

- Prevention of grinding media loss, very easy cleaning and ease of use

- Reliable use of micro grinding beads in the range of 30 μm - 300 μm

- No screen blockage thanks to the ODC/SDC separation system

- Variety of materials available for grinding systems (can be interchanged)

- Large selection of grinding chamber materials (can be combined)

Request Product

Technique

- Fives sizes with 2 l, 4 l, 10 l, 25 l and 60 l grinding chamber volume

- Peg grinding system with small length/diameter portion

- ATEX-conform design in ergonomic design

- Highly efficient dynamic centrifugal separation system

- Use of smallest grinding media from 50 to 300 µm

- Integrated grinding media collecting tray for loss-free emptying

- Easy handling due to swiveling and carriage-type grinding chamber

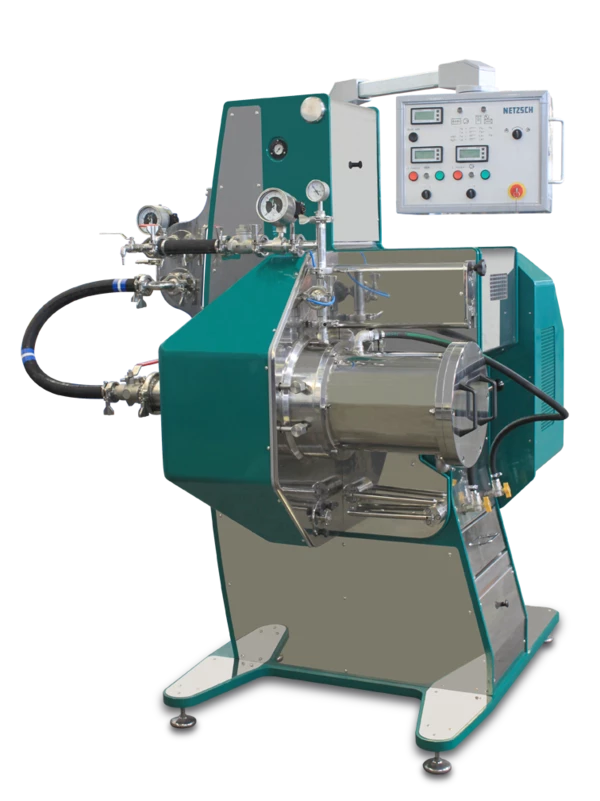

- Control of the mill drive and feeding pump via frequency inverter

- Flow meter to control the product flow

- Pressure control by contact manometer

- Measurement of the product inlet and outlet temperature, optionally also available for cooling water temperature

- Flow measurement of the chamber cooling

- Grinding chamber design of stainless steel as standard. Wear and corrosion resistant designs for metal free processing are available in the materials NETZSCH Ceram_C / NETZSCH-Ceram N, NETZSCH-Ceram Z, NElast

Handling

During development of the Zeta®RS machine series, special emphasis was placed on ease of use. Filling and emptying as well as servicing and cleaning the machine are easily accomplished without the loss of grinding media.

- Positionable grinding tank

- Integrated, removable grinding media collection tray

- For even greater usability, an optional swivel-mounted grinding chamber is available for models Alpha®Lab, Zeta®RS to Zeta®RS 10

Filling Position

Operating Position

Emptying and Cleaning Position

Your Contact at NETZSCH

Any specific questions? Contact us for help.

you may also be interested in: