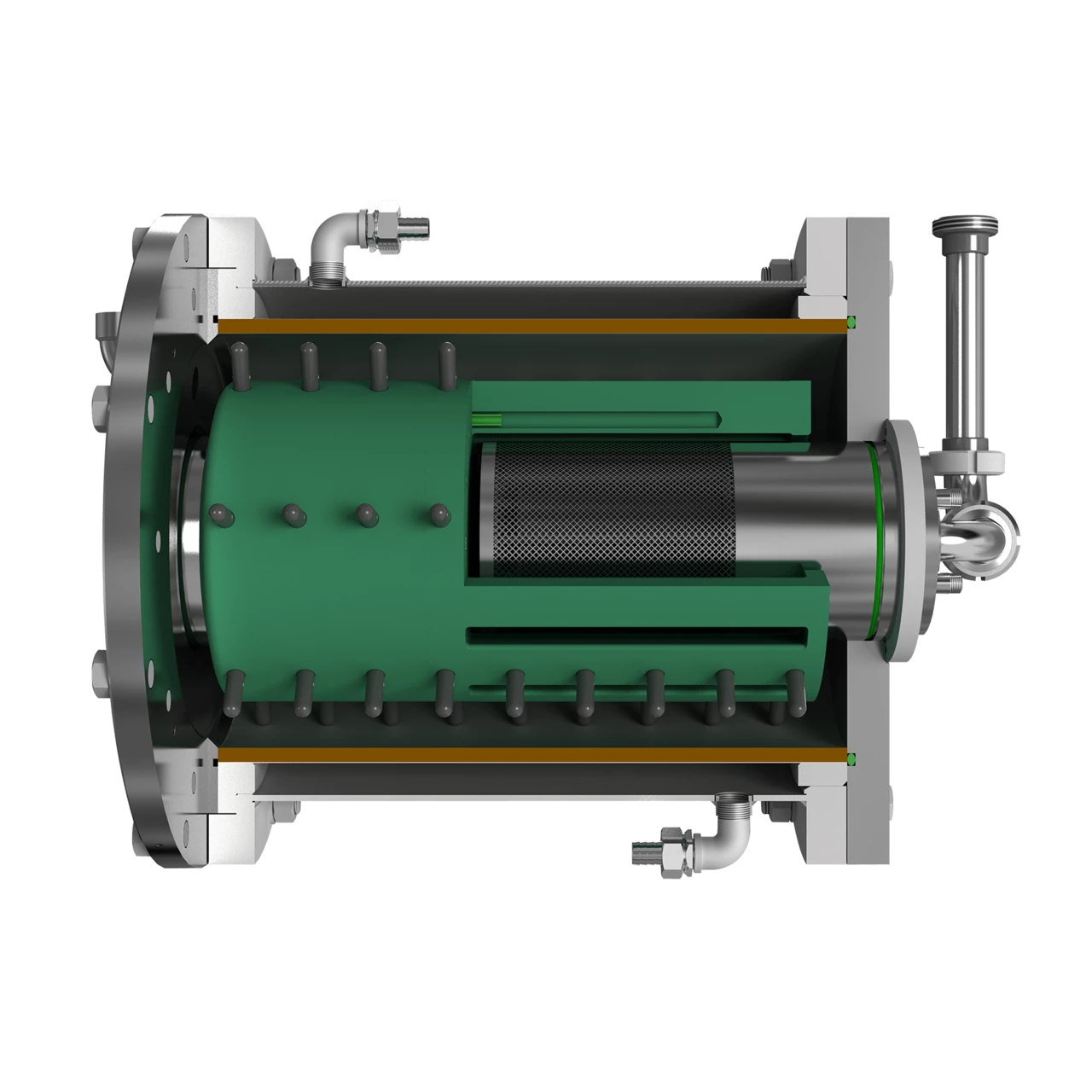

The agitator bead mill with the newly-developed Neos grinding system stands for maximum performance, product quality and efficiency. Coupled with the reliable use of extremely small grinding media, you can achieve your required product quality with high production output and low specific energy consumption.

During the design phase, particular attention was given to achieving maximum cooling efficiency. As a result, it is possible to stay within the required temperature limits even with high power input. This means a significant increase in production output compared to similar grinding systems.

Focus on Your Advantages

Grinding System Neos - Increase your Production Capacity!

- The highest power input without overheating the product

- Maximum volume throughput

- The highest cooling efficiency

- Use of extremely small grinding beads (0.1 to 0.8 mm)

- Reproducible product quality

- High degree of process reliability

- Low operating costs

- Conversion of existing machines to the latest technology

Request Product

Performance & Efficiency

High Power Input

A high power input is achieved with the new grinding system Neos which realizes a high productivity.

Reproducible Product Quality

Store your product formulations in the control system and achieve reproducible qualities in the production process.

Upgrade Zeta® --> Neos

Do you want to keep your existing Zeta® machine but also benefit from the advantages of the new Neos grinding system? We offer an upgrade to Neos for Zeta® models.

Maximum Volume Throughput

In the circulation operation mode, the required number of cycles is achieved very quickly due to the extremely high volume throughput.

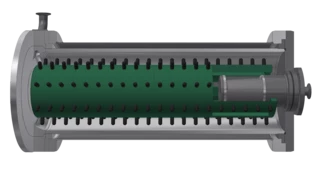

Stable Production Process

The optimal grinding media separation and maximum slotted pipe surface area ensure that the grinding process remains stable even with minor changes in process conditions (temperature fluctuations, formulation variances, viscosity changes, etc.).

Optimized Cooling

The highest cooling efficiency results from the use of new materials and optimum utilization of the available cooling surface.

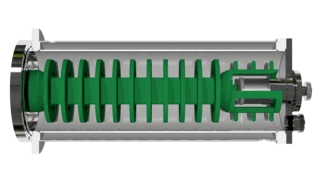

Use of extremely small Grinding Media

Select the right size of NETZSCH Zeta® - BeadsPlus for your process.

Preventive NETZSCH Service

Optimal maintenance along with the analysis of plant and machine data by our NETZSCH Service team increases the productivity and service life of the machine.

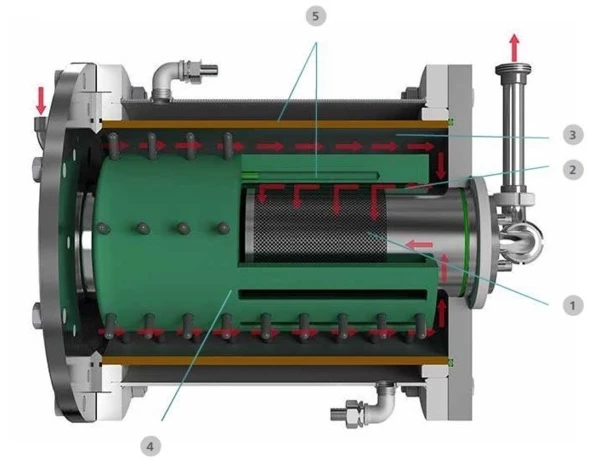

Features of the Neos grinding system:

- Maximum slotted pipe surface area

- Optimized grinding media separation

- Maximum cooling surface to grinding chamber volume ratio

- New rotor design for efficient power input

- Optimum grinding chamber cooling with NETZSCH-Ceram C inner tank and optional rotor cooling

Sucessfully Implementated Projects

Test the new Neos grinding system at our pilot plant

NC Flexo Printing Inks

During production of an NC flexo printing ink with a Neos 20, a net power input to the grinding chamber of 37 kW was possible without reaching the temperature limit of the product. In the existing process with a standard machine, the temperature limit was met with a net power input of 23 kW.

With the use of the new Neos in combination with optimized process parameters, the production performance was increased to more than 200% when employing a comparable machine size.

Textile Inkjet

For the processing of Digital Ink, covering decorative, packaging and functional inkjet, Neos grinding system is also the optimal machine, in terms of design and materials selection. In the case of textile inkjet grinding, our customers are getting results 30% - 40% better in terms of productivity to use of other peg-counter pegs systems available in the market.

Neos provides in our grinding chamber sizes from 10 l - 50 l a perfect temperature control below 45°C.

Your Contact at NETZSCH

Any specific questions? Contact us for help.

you may also be interested in: