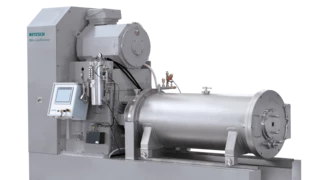

Compared to other systems, the Salsa® system stands out for its lower requirements for power, cooling water and space, and for its shorter processing times.

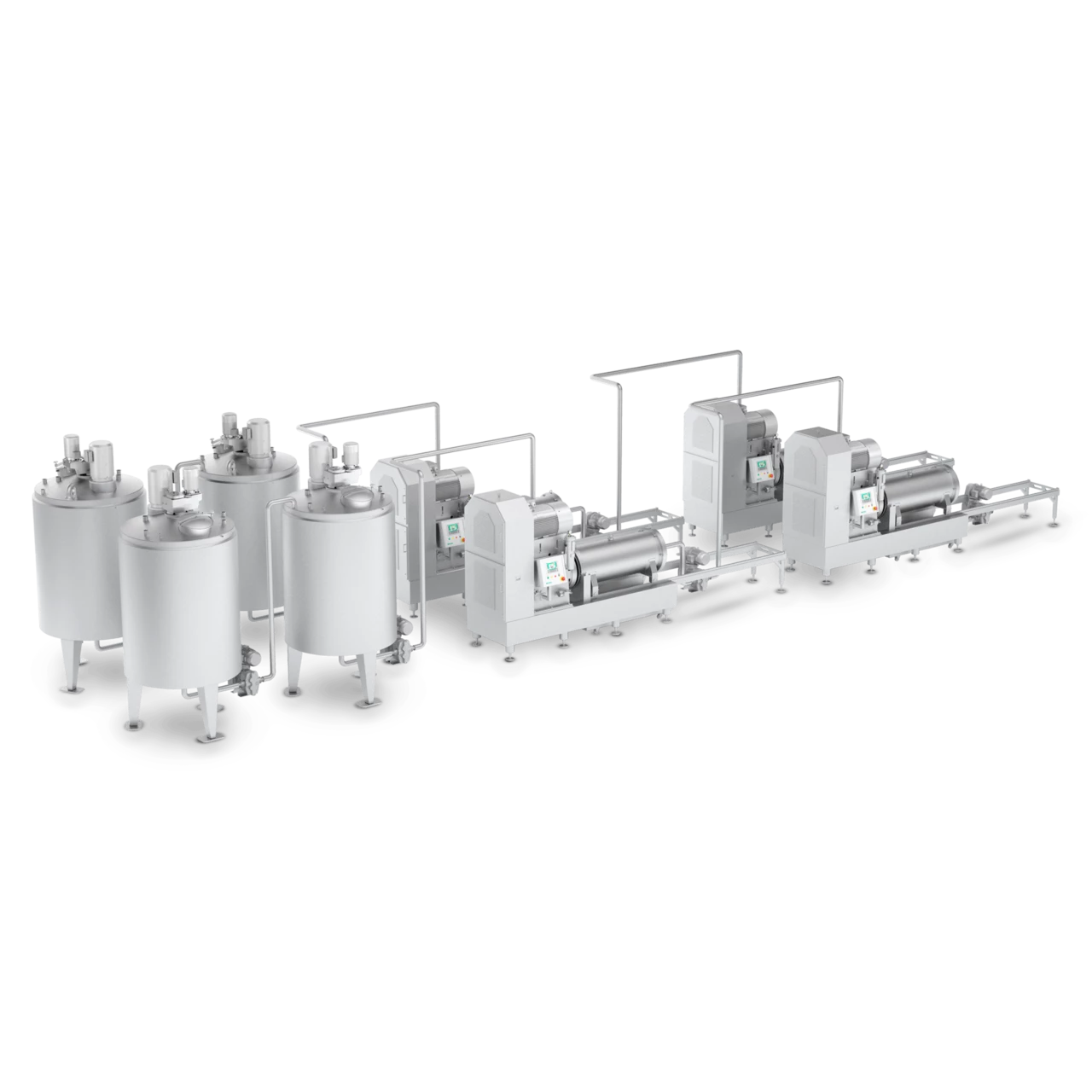

Thanks to the modular construction, the plant is designed according to your exact requirements. The plants can easily be expanded at a later time.

Our line concept Salsa® includes the initial homogenization of the individual components in a mixing tank with a rapidly spinning dispersion tool for product circulation, transfer of the mass to the heatable process tank and the final fine grinding in the MasterRefineragitator bead mills.

Optionally, our systems can be equipped with a feed station and fat-melting system, for example.

With the Salsa® system you achieve the best reproducibility in a defined semi- or fully-automated process. The simple, menu-guided control system, which includes temperature control, allows exact adjustment of your desired quality, with end finenesses < 15 μm possible.

Focus on Your Advantages

Request Product

Technique

The production capacity of a plant is dependent on the size of the MasterRefineragitator bead mill (with Samba system) employed. In addition it is strongly dependent on the initial fineness of the sugar used.

| Mill type | Throughput capacity [kg/h] * | |

|---|---|---|

| Granulated sugar < 1.5 mm | Pre-ground sugar < 250 μm | |

| MasterRefiner 6 | 45 | 50 |

| MasterRefiner 30 | 150 | 180 |

| MasterRefiner 60 | 300 | 360 |

| MasterRefiner 150 | 600 | 720 |

| MasterRefiner 200 | 900 | 1080 |

| MasterRefiner 300 | 1200 | 1440 |

| MasterRefiner 500 | 1800 | 2160 |

* at an end fineness of 25 μm. End finenesses < 15 μm are possible with adjusted throughput. Assumes a maximum sugar content of 50% and a fat content of 30%.

Your Contact at NETZSCH

Any specific questions? Contact us for help.

you may also be interested in: