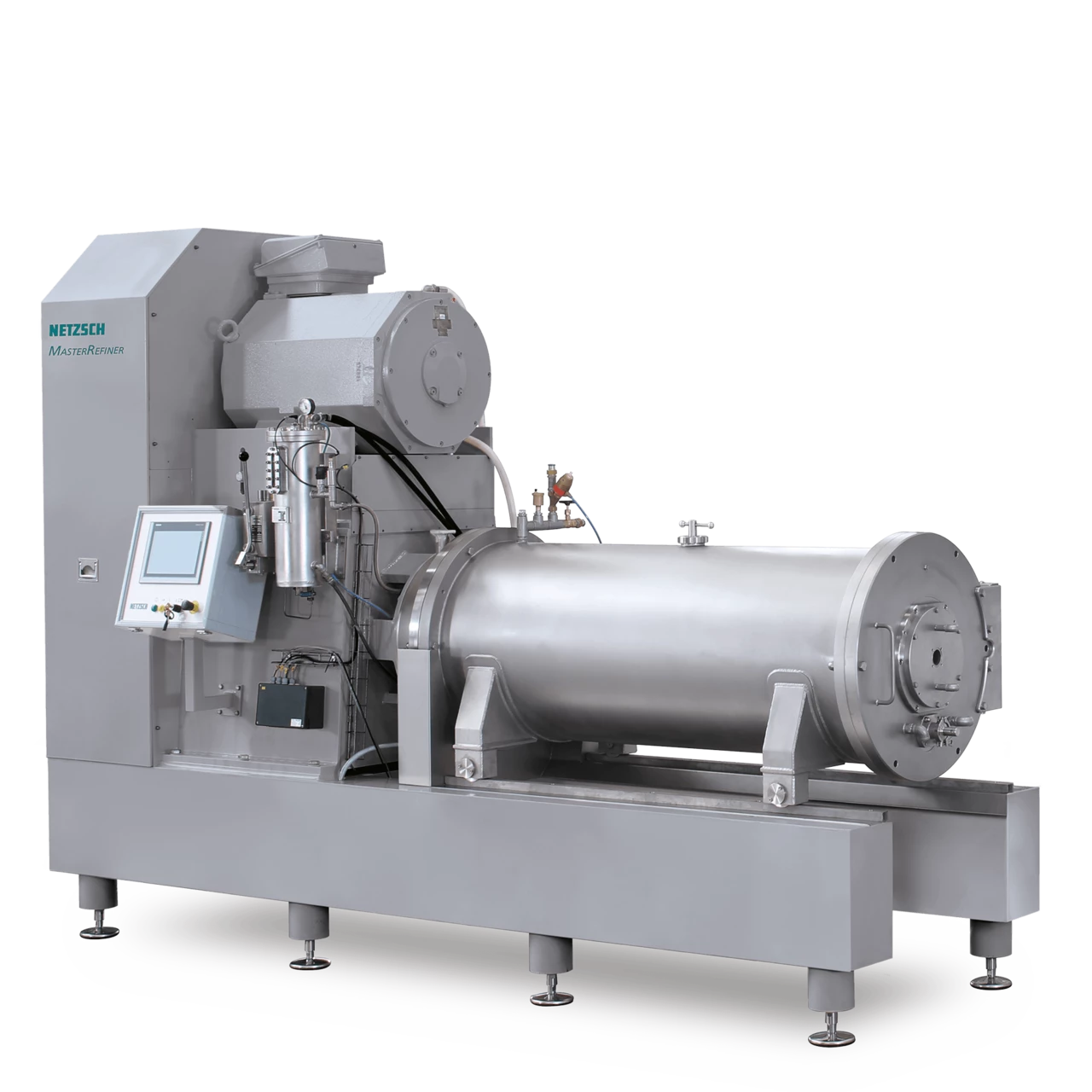

The horizontal disk mills type MasterRefiner are improved, continuous working laboratory and production machines for wide variety of food and confectionery applications.

The disk agitator shaft activates the grinding media with high intensity through the entire grinding chamber. Highly efficient separation devices that are adapted to your application are available for separation of product and grinding media. This ensures that the mill is reliably operated with high viscous products as well. Depending on the product-specific requirements, the machine can be designed in different materials (e.g. NElast, rubber, ceramics, chilled casting, special steel).

Technique

- Highest product quality at exact reproducibility

- Narrow grain spectrum down to the sub-micron area

- Flexible work with short preparation times

- Easy handling

- Continuous grinding process with high energy density

- Grinding chamber designs adapted to your product

- Abrasion-proof wear parts of different materials

- Use of grinding media from approx. 0.5 to 5 mm

- Classifying separation system for all types of smallest grinding media

- High productivity at lowest space requirement

Request Product

Videos

NETZSCH Single Pass Operation LME

NETZSCH Pendular Operation LME

NETZSCH DCC Separating System LME

Your Contact at NETZSCH

Any specific questions? Contact us for help.

you may also be interested in: