NETZSCH Rounding Unit GyRho – High-yield scalable process

The system developed by NETZSCH has overcome all the disadvantages of the standard technology and delivers a smart solution for producing spheroidized graphite in an efficient and optimized process.

In the first step, flake graphite is micronized to the optimum initial particle size for spheroidization in a classifier mill or fluidized bed jet mill. Particle rounding takes place downstream in the newly designed NETZSCH Rounding Unit GyRho, which is available in various construction sizes and can be specially designed to suit the necessary output requirements. For larger throughput volumes, two (or more) machines can be operated simultaneously.

Your benefits of the single machine process

Technical data of an industrial plant

- Capacity: 25,000 t/a

- Air volume: 120,000 Nm3/h

- Installed power: 7 MW

- Filter area: 1,500 m2

- Dimension: 60 m x 16 m x 23 m (l x h x w)

NETZSCH – Expertise to improve the overall yield to 85%

The NETZSCH Process

In the first step, micronization takes place in a proven standard procedure with classifier mills to obtain flake graphite with a defined particle size. The subsequent spheroidization process is conducted batchwise.

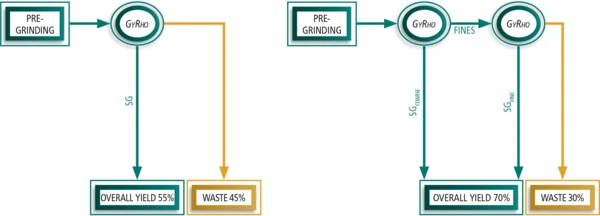

Since the maximum throughput for micronization is higher than the capacity for spheroidization, a setup to match both throughputs with a certain combination of machines must be found. This combination is defined as a cluster. An example of a typical cluster for standard operation is one grinding mill with a 1200 kg/h throughput and four spheroidization units with a capacity of 300 kg/h each. The yield can be calculated for each single machine. NETZSCH has developed various approaches to re-use fines from the first spheroidization step since those fines are usually considered as a low value stream or waste.

To improve the overall yield, there are several options to combine certain process steps. The easiest way is to use the fines from the first spheroidization step and feed it directly into a second GyRho Rounding Unit. This process produces two qualities of Spherical Graphite (SG) and an increase in yield of about 15%, from initially 55% to 70% in total yield.

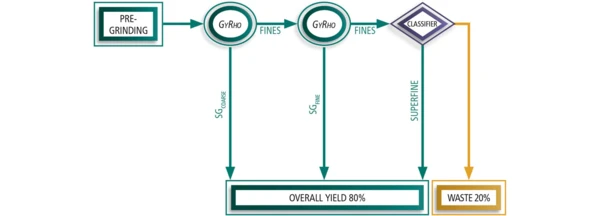

A further improvement of the 2-step process is the integration of a classification step into the waste stream of the fines after the second spheroidization step. With this design, it is possible to generate two very fine fractions of the material, which was defined as waste. Although this is no Spherical Graphite, one of these fractions is a saleable product and reduces the amount of total waste again. This concept achieves overall yield rates of up to 80%.

One step further

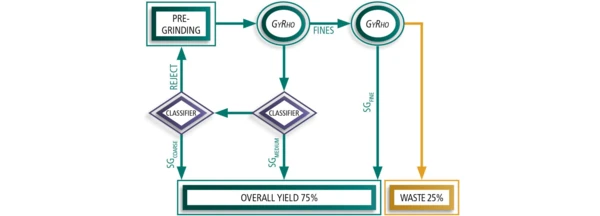

Additional versatility in the design of the 2-step process is possible, when additional air classifiers are included into the concept.

The first improvement is the possibility to process coarser feed material, because commercial Spherical Graphite is not directly produced in the first step. The coarser feed includes less initial fines, which improves the overall yield. The fine product goes directly to the second GyRho Rounding Unit and the process is the same as in the 2-step process described before, a fine SG-fraction and a waste fraction are produced.

The main share received from the first rounding step is a fraction of Spherical Graphite with a broad particle size distribution. This is separated in the first external classifier into a fine fraction with a very steep particle size distribution at a d90/d10-ratio in the range of 2 plus an additional coarse fraction. Different from all previous steps both fractions are SG-products. The coarse fraction is fed directly into the second classifier and again a fine SG-fraction with a very steep particle size distribution is achieved. The remaining coarse fraction is recirculated into the initial feed stream of the process, reducing the amount of coarse material reporting to the product and increasing the total yield.

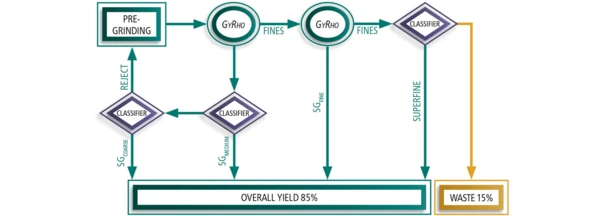

Analogous to the 2-step process with classification a further optimization is possible with the implementation of a classification step into the waste stream. In this way, it is again possible to produce two very fine fractions and to reach an additional useable fraction of a superfine Graphite to reduce the amount of waste. A total yield up to 85% is achieved with a concept that is shown below.

NETZSCH Rounding Unit GyRho – High-yield scalable process

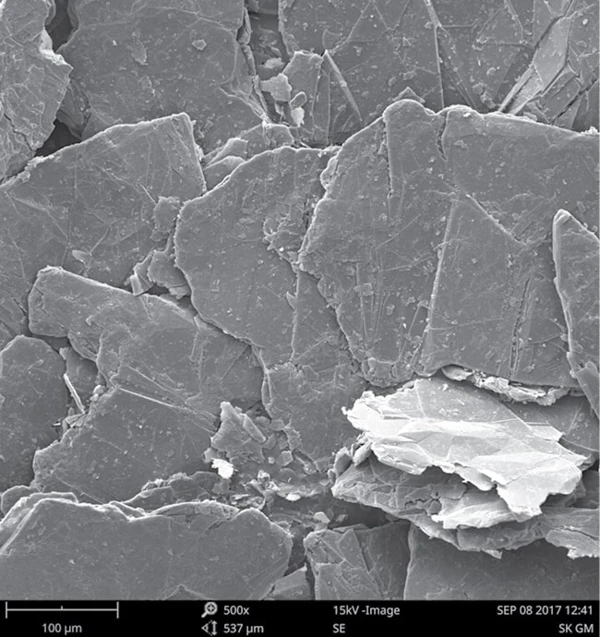

Several process combinations are possible to achieve overall process optimization and improve yield. In terms of process comparison, it is essential to develop a base case process, which is used to compare different parameters like feedstock or quality. This kind of research can be done in the test lab of NETZSCH Trockenmahltechnik in Hanau. In the lab trials, all main quality criteria like particle size distribution, tap density, particle morphology via SEM-Pictures or the specific surface area are analyzed.

In summary, process optimization improves the overall yield of Spherical Graphite from a standard value of about 55% to a total yield above 80%. These increased yield rates are possible with the combined production of different qualities of Spherical Graphite. To produce several qualities according to highest standards the flexibility of the process is essential. The classification shapes the specific values of each product and optimizes the corresponding streams. Only with this concept, highest throughput rates are possible in the spheroidization step.