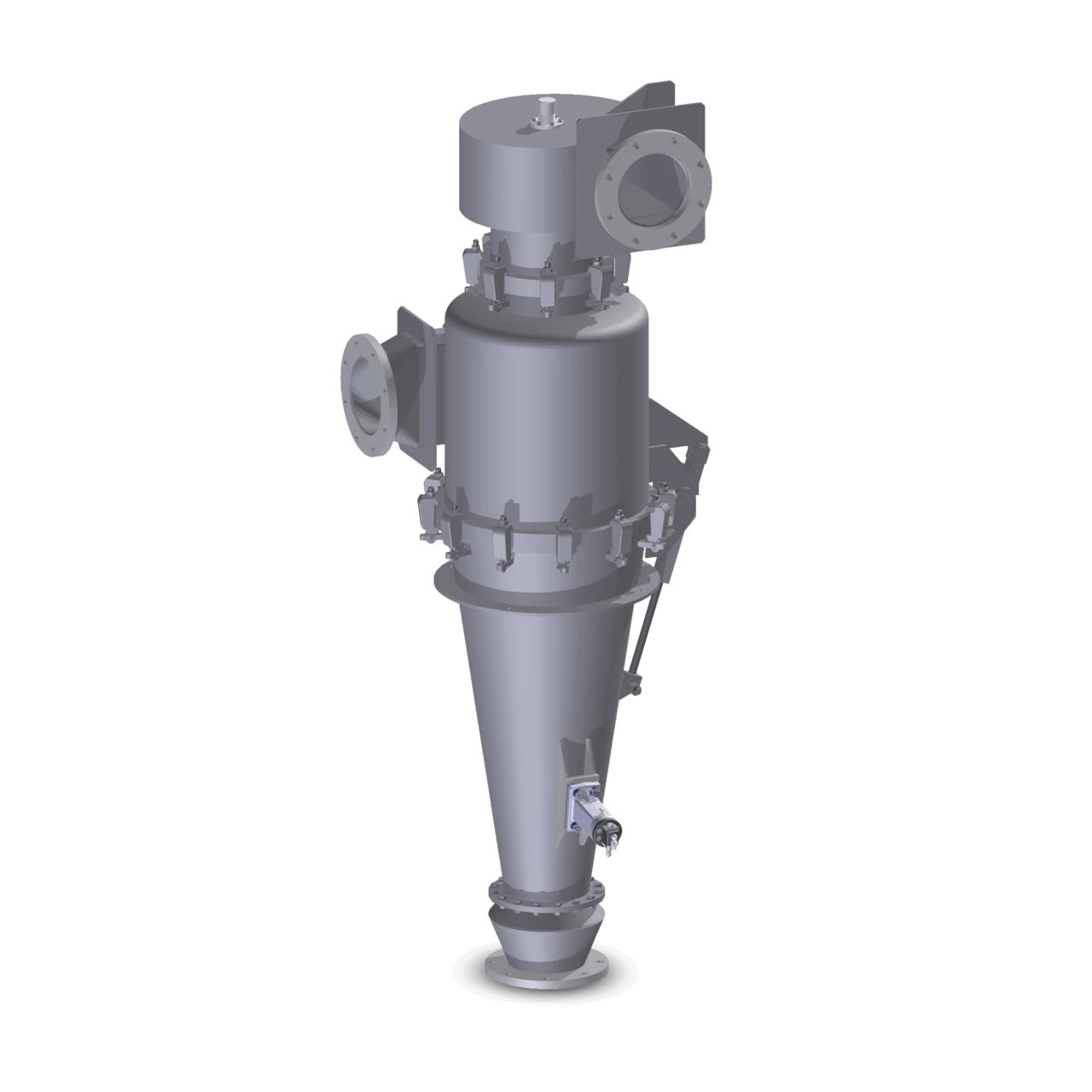

Cyclone or centrifugal separators are used in grinding- and classifying plants for separating the product out of the gas flow.

The gas loaded with product enters the cyclone tangentially via the inlet spiral and is then set in a rotating motion. In the vortex the coarse particles are transported outwards by centrifugal force and then separated out through the product outlet. Small particles leave the cyclone at the gas outlet with the gas flow after a vortex reversion (secondary vortex) upwards through the immersion tube. With a NETZSCH cyclone you can achieve a degree of separation of up to 99.9%* depending on the product and fineness.

* Example: Product density = 7.87 g/cm3, fineness d97 = 11.2 µm

Focus on Your Advantages

Request Product

Executions with NETZSCH Cyclones

- With spiral hood for vortex-free gas outlet and conditioning hopper which prevents entrainment of the separated product in the secondary vortex

- Separation flange, can be optionally equipped with swivel device with manual winch or in hydraulic variants for simplifying demounting and cleaning

- Pressure shock resistant execution up to 10 bar(g) possible

- Materials normal- (1.0037) or stainless steel (1.4301, 1.4404, 1.4541, 1.4571)

- Surfaces and coatings:

- Ground

- Polished

- PU, Teflon or ceramic coatings

- Further executions upon request

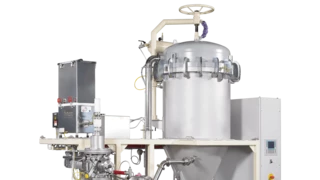

Use of Cyclones

- For use when frequent product change is required, for example in laboratory area

- In plants which are run with many different milling settings

- In plants which must be cleaned frequently (product characteristics, product change)

- To avoid contamination of the product with filter material (fibers)

Downloads

Your Contact at NETZSCH

Any specific questions? Contact us for help.

you may also be interested in: