Glossary

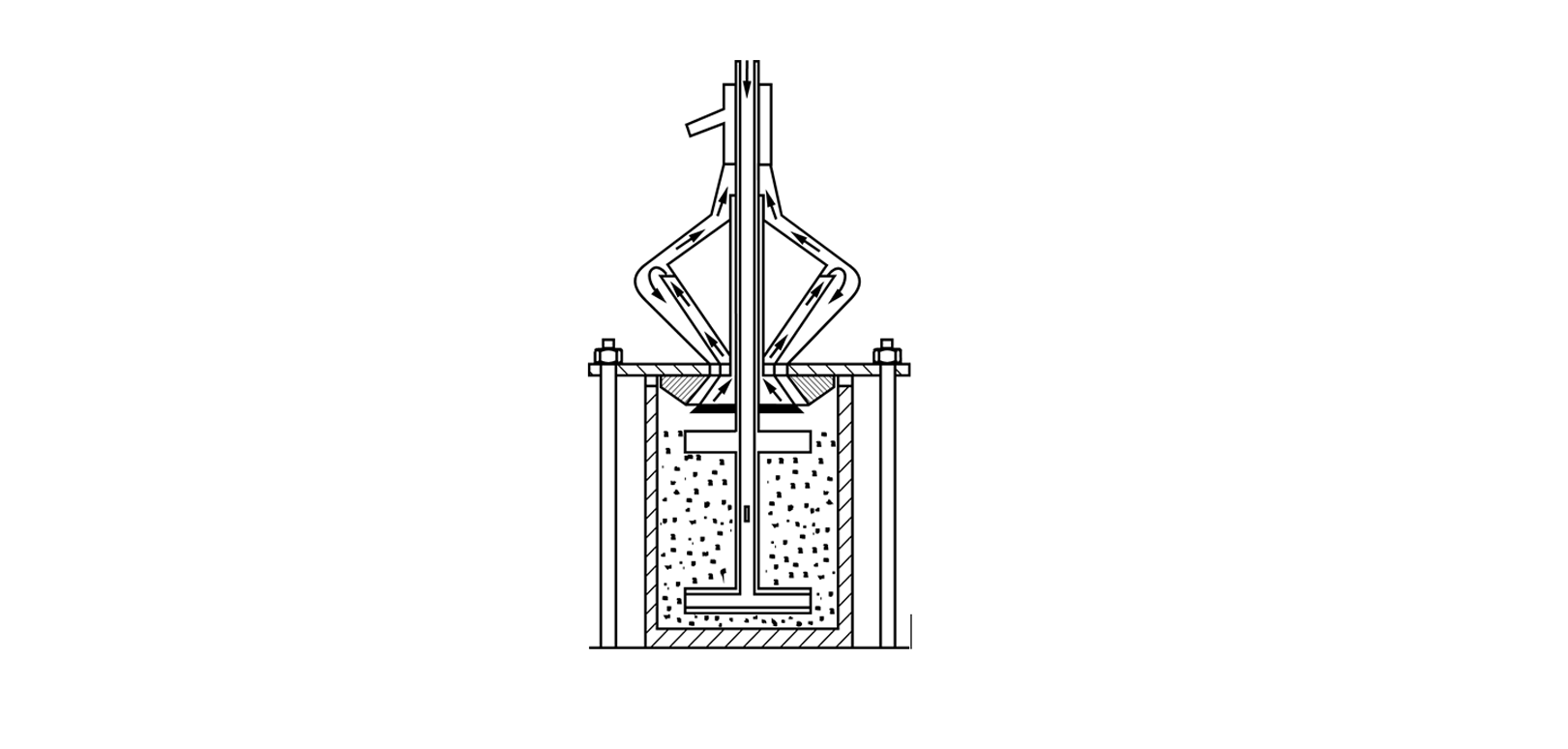

Attritor Mills

are special designs of agitator bead mills and are among the slow-running mills with circumferential speeds of approx. 0.5 m/s -2 m/s. Some of them are still used today for the comminution of abrasive hard materials such as silicon carbide.

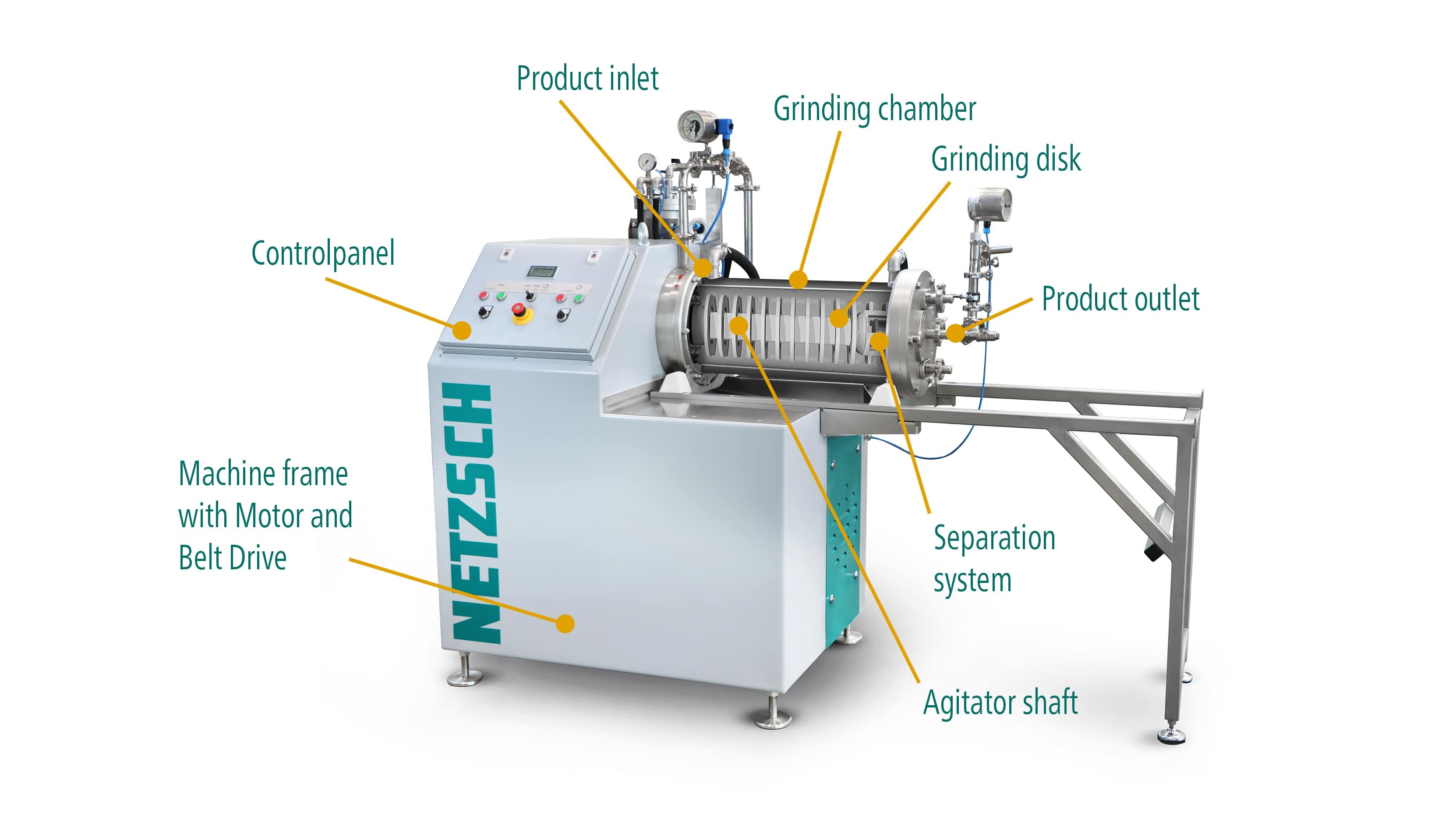

In the case of continuously operated horizontally arranged agitator bead mills, the product suspension is pumped into the grinding vessel at the front via the product inlet.

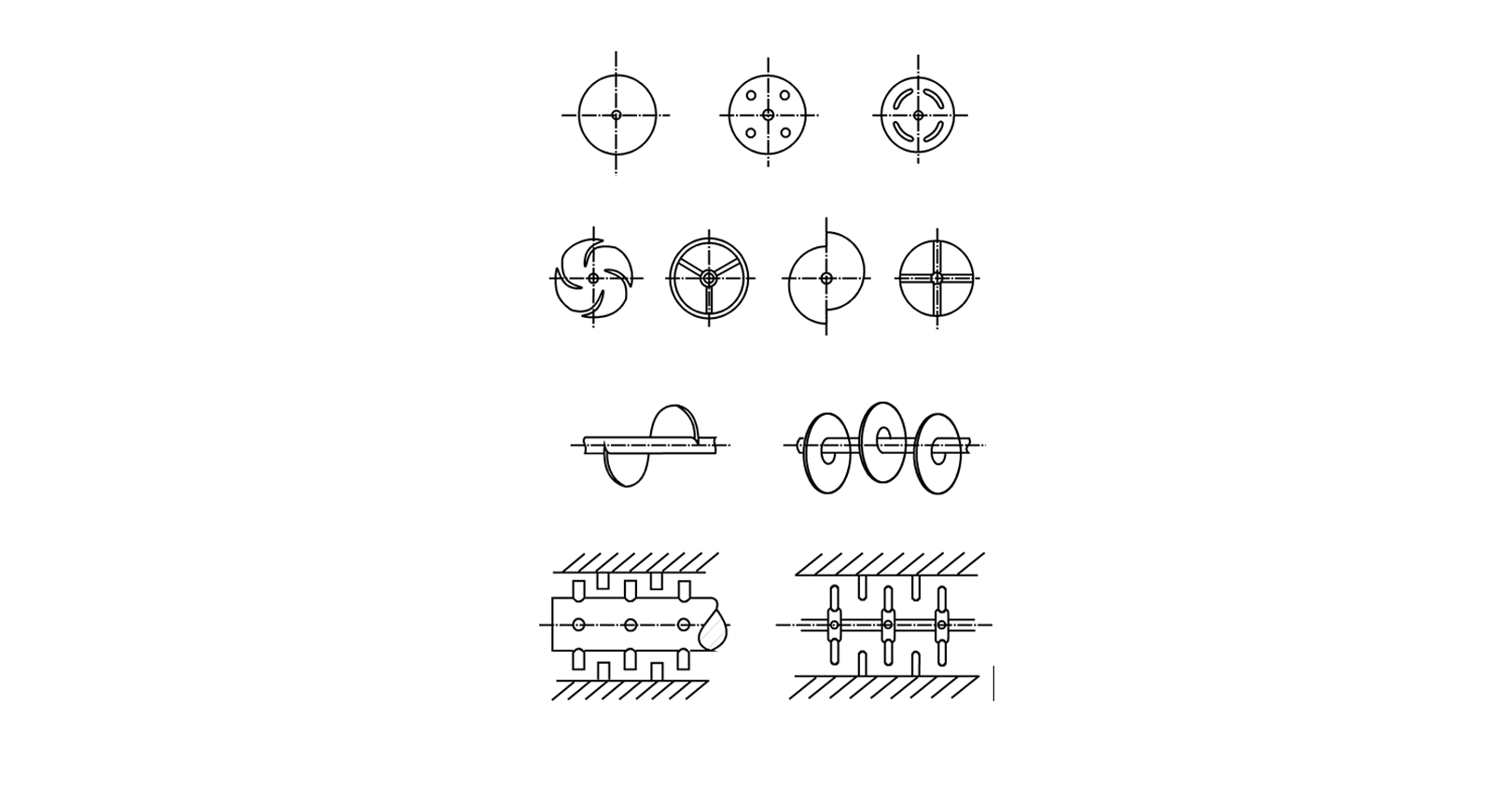

The agitator is located in the grinding chamber. In this case, agitating elements in the form of solid discs, perforated discs, pins, pegs or other elements are generally arranged on an a agitator shaft. The agitator shaft is operated at circumferential speeds of up to 20 m/s.

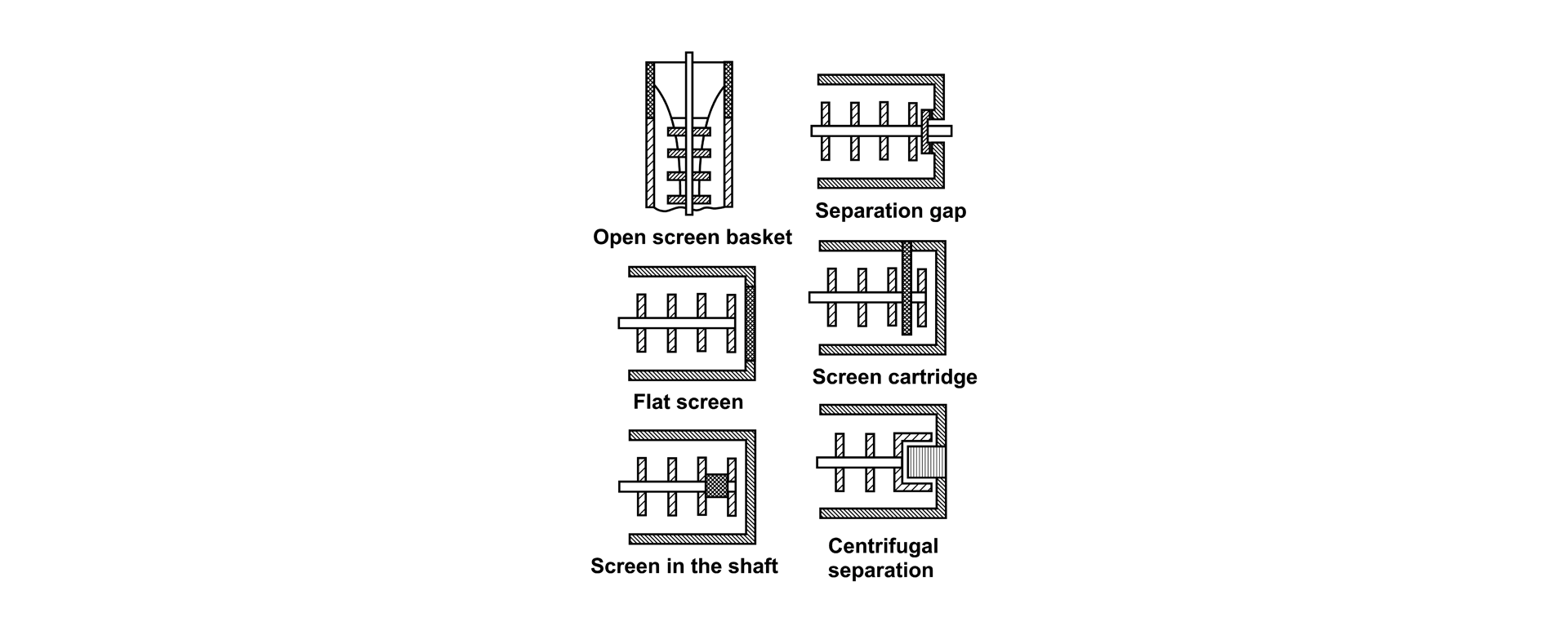

The grinding chamber is usually filled with 70 - 90 % bulk volume with grinding media. The product suspension leaves the grinding chamber via a grinding media separator. This can be designed as a friction gap or as a screen cartridge, for example. In order to cool the machine, the grinding vessels are usually double-walled.

At NETZSCH-Feinmahltechnik GmbH, the development led to the development of different grinding chamber and agitator shaft geometries, which are suitable for a wide variety of applications depending on the properties of the product suspensions and the product and quality requirements.