Carbon Materials

Process Technology for the Rounding of Graphite

Due to its use as a material for anodes in lithium-ion-batteries, graphite is of great importance in the context of electromobility.

Graphite is the stable modification of carbon under normal conditions and has been used for many years in various sectors such as the steel- and automotive industries.

In the next few years, the area of renewable energy, which is experiencing extremely rapid growth in the context of electromobility, will offer the highest growth potential for graphite, as it is used as a raw material for anodes in lithium-ion-batteries. Approximately 10 – 15 times more graphite than lithium is required for one lithium-ion-battery.

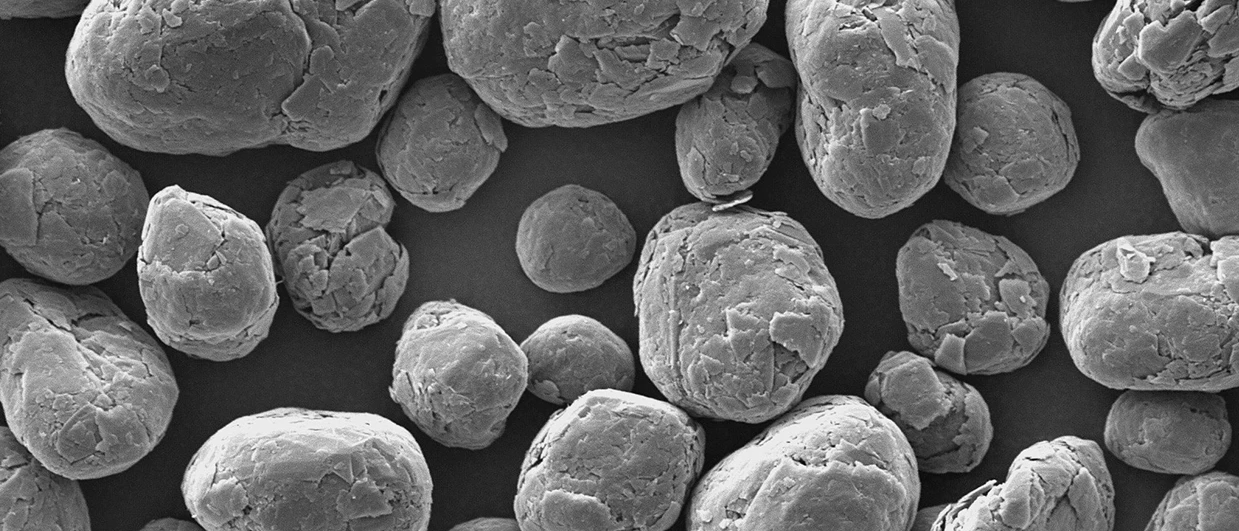

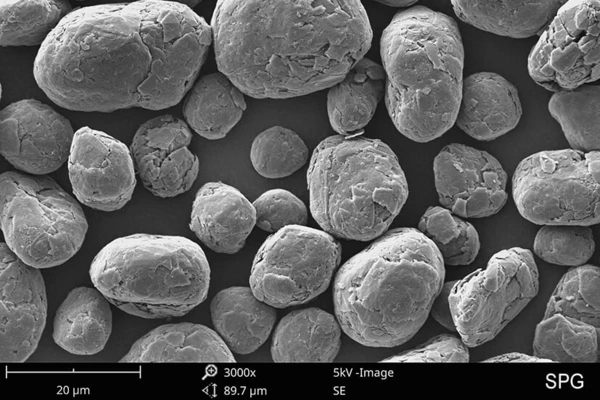

Globally, graphite occurs most commonly as so-called flake graphite, which are graphite flakes containing only a small proportion (maximum 20 %) of actual graphite finely distributed in stone. This natural graphite must be processed using various methods in order to obtain the final product which is used for battery applications and has a purity of over 99.95 %. As well as the chemical purity, the morphology of the graphite also plays a decisive role.

Spherical graphite (SG) is ideal for use as a raw material for anodes. Its smooth, small surface prevents flaking and ensures low irreversible capacity loss and long service life. Due to its high tap density, high charging is achieved and consequently energy density is higher.

Contact Applications

Efficient Rounding of Graphite with the NETZSCH Process

The NETZSCH business unit Grinding & Dispersing and Dorfner ANZAPLAN have joined forces to find a more efficient solution for graphite rounding to overcome the disadvantages of the previously widespread used process requiring more than 20 classifier mills installed in rows:

In a first step, the flock graphite is pre-ground to the optimum initial particle size for spheroidization in a classifier mill or fluidized bed jet mill.

The actual particle rounding process takes place directly downstream in the newly designed NETZSCH GyRho Rounding Unit which is available in various construction sizes and can be specially designed to suit the necessary output quantity. For larger throughput volumes two (or more) machines can be operated simultaneously and can replace the train of 20 machines or more as mentioned above.

With specific settings, it is possible to achieve the maximum yield of final product with the desired quality. Quality criteria such as distribution width, tamped density and particle size can be influenced by varying the process parameters.

In this way, using the newly developed NETZSCH GyRho system, all qualities required by the market, such as spherical graphite with a tap density of 963 g/l and a d50 value of 16.8 µm (yield based on a raw material volume of 60.7 %) are achievable.

Your Benefits

Plant data for the NETZSCH GyRho System compared to competitors´ systems

30 % higher plant availability

65 % total yield*

* up to 65 % total yield based on amount of raw material and depending on its origin and type

35 % lower operating costs*

* Opportunity-, working-, spare part-, electricity costs, depreciation and costs for graphite concentrate