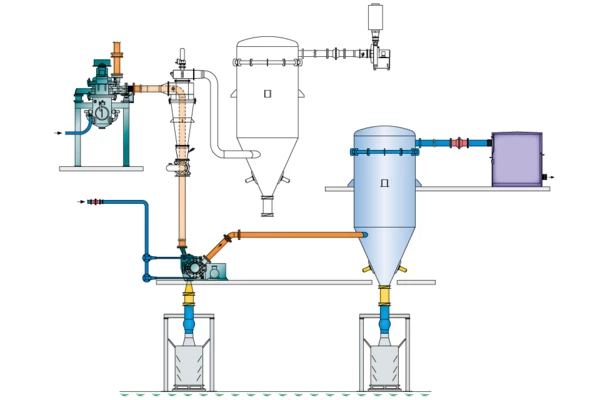

The combination of a fine grinding mill with a downstream air classifier is unavoidable for many product applications. The newly developed InlineStar however, can distinctly reduce the necessary expense!

An In-Line classifier combined with a fine grinding mill enables one to reduce the number plant components and energy! The intermediate separation of the product after the grinding stage is no longer required eliminating the need for cyclone, filter and exhaust blower.

The classification results are impressive. The sharpest separation, highest fineness and maximum possible yield is achieved!

The new InlineStar is available for testing in our laboratory in Hanau.

Request Product

Technique

- Finenesses up to d97 2.5 µm (based on limestone)

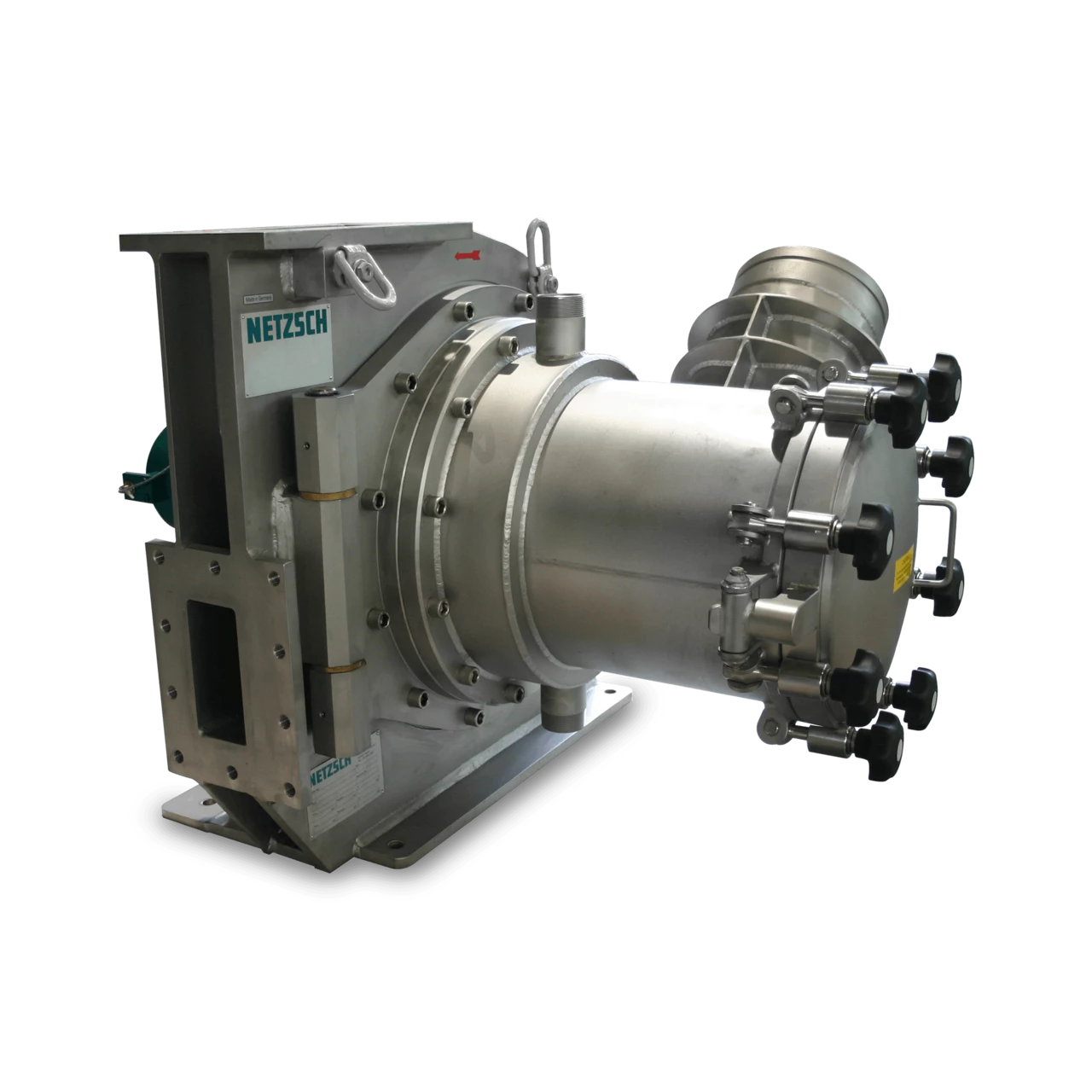

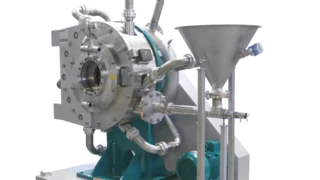

- High performance classifier with horizontal shaft

- Inline classifier for direct integration behind a fine grinding mill

- Lower total air consumption

- Welded classifier housing with hinged door for very good access for fast, easy cleaning and maintenance

- Guide vane ring with adjustable vanes for efficient dispersion of the feed product prior to classification

- Classifier wheel with exchangeable, simultaneously rotating immersion tube to achieve highest finenesses, unlimited adjustment

- Gap between classifier wheel and fines outlet rinsed by gas for highest possible prevention of oversize particles in the fine fraction

- Classifier shaft seal rinsed by compressed gas to protect the bearings

- Bearing of the classifier shaft is permanently grease sealed or oil lubricated for hot gas applications

- Extremely sharp separation and improved fines extraction

- Highest finenesses and maximum throughput achievable with just one classifier wheel

- Even load of the classifier wheel through the rotationally symetrical design of the machine

- Reproducible results

- Simpler system assembly with fewer plant components and reduced space requirement

- Optional designs available: pressure shock resistant, gas tight, wear protected

Your Contact at NETZSCH

Any specific questions? Contact us for help.

you may also be interested in: