식품 & 제과제빵 산업

Special Flours / Protein Shifting

Grinding and Classifying

with Higher Throughput Capacity

The worldwide nutritional demand for plant-based proteins is increasing enormously. The main sources are soybeans, wheat or peas. More often, regional crops such as faba beans are being taken into consideration.

Semimanufactured products are amongst others protein-enriched flours or isolates using wet- or dry processes or a combination of both.

NETZSCH focuses itself on protein shifting by dry grinding. This process, taken from classical flour production, is being used successfully to process legumes such as yellow peas, faba beans, mung beans or chickpeas.

The aim of the process is to gain a protein-rich fraction by fine-grinding and classifying, in which the amount of protein is considerably higher than in the original product.

Contact Applications

Example of an Application

Legumes

Processing step 1 – Production of refined flour

Ideally the cleaned legumes are dehulled prior to the protein shifting process to a residual portion of < 1 %. The refining serves to break the cell structure and to isolate the relatively large starch granules from the smaller protein granules. Depending on the product, the proteins have a particle size of < 3 µm, whereas the starch granules range from 3 to 40 µm.

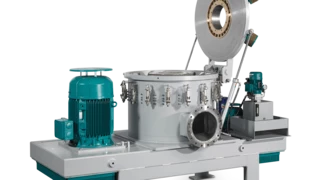

Most important for the subsequent separation, is that during grinding, the difference in size between the protein and starch granules remains as large as possible. Care must be taken to not damage the starch granules in the process. The most effective and gentle way to achieve this is through impact grinding in a NETZSCH Classifier Mill, model CSM.

Processing step 2 – Efficient separation using a high-efficiency classifier, model CFS/HD-S

The resulting refined flour has a particle size between 40 and 70 µm and is then separated into a high-protein and low-protein fraction. This is a range that brings conventional sifting to its limits. For this reason, the fractioning for protein shifting is carried by dynamic air classifiers.

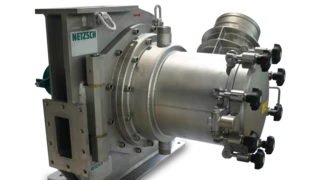

The NETZSCH High-Efficiency Fine Classifier, model CFS-HD/S is used to achieve the highest yields with a minimal loss of protein in the high-starch fraction.

As opposed to conventional classifiers, this classifier is highly compact and is equipped with a guide vane cage for most efficient dispersion and separation – the decisive advantages when viewing the economics of protein enrichment!