식품 & 제과제빵 산업

Hydrocolloids

Food Additives and Food Supplements with many different Properties

A large group of polysaccharides and proteins which have a high capacity for gelling are known as hydrocolloids. A large number of these originate from nature most of them from the plant world. However, hydrocolloids can also be obtained from algae, bacteria and animal sources. The extraction of hydrocolloids is carried out using several very different processes and often the products obtained are further modified in order to regulate certain properties.

Hydrocolloids are used in the food industry as gelling- and thickening agents, stabilizers, humectants etc. Furthermore, their properties give each particular food its appearance and the usual (texture) mouth feel.

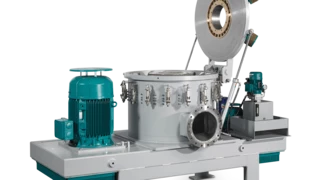

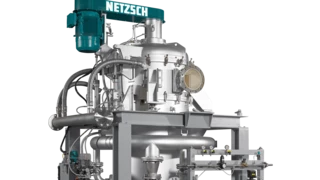

We can offer you the optimum solution for your requirements with NETZSCH´s proven technology including impact-, classifier-, jet- and fine-grinding mills.

Contact Applications

Application Example

Pectin

Pectins are plant-based polysaccharides which can be found in all hard plant parts, for example stems, flowers or leaves. Seen from a nutritional point of view pectins provide dietary fiber for humans, although they are used chiefly as gelling agents in the food industry. Pectins are essential ingredients of many products in the food- and pharma industries or are used in the manufacture of cosmetics.

| Machine | Throughput [kg/h] | Final Fineness [µm] |

|---|---|---|

| SecoMy® S 50 | 11 | 90 (d90) |

| CSM 720 | 700 - 800 | 179 (d90) |

Application Example

Algae

Algae not only have a high content of minerals and trace elements, but are also rich in carbohydrates, unsaturated fatty acids and/or beta-carotenes. For this reason algae are interesting as a food – so far predominantly in South East Asia.

For special applications the individual ingredients are used or the degradability of algae is exploited and the products obtained through degradability used.

| Product | Machine | Throughput [kg/h] | Final Fineness [µm] |

|---|---|---|---|

| Chlorella-Algae | ConJet® 32 | 19 | 7.5 (d50) |

Application Example

Cellulose and Cellulose Derivatives

Before cellulose and cellulose derivatives can be used in pharmaceutical products, a multistage processing is necessary.

With their precise and high number of cuts and the use of a screen insert and/or with a rotating classifier wheel to determine the final size, the fine-grinding mills CS-Z, SecoMy® and SecoMy® S by NETZSCH are an ideal solution for the first processing step. The cellulose powder obtained with these machines can be added straight away to the product (food) as a filler or an additive.

The powder obtained in this way can also be modified and by introducing various functional groups can give a multitude of cellulose derivatives which are characterized by certain particular properties such as solubility, viscosity, gelling power and -temperature or surface activity. With the NETZSCH impact mill the cellulose derivative can be ground down to various finenesses to suit your requirements exactly

| Product | Machine | Throughput [kg/h] | Final Fineness [µm] |

|---|---|---|---|

| Wood cellulose | SecoMy® S 50 | 45 | 63 (d97) |

| CMC | Condux® 1250 | 1800 - 2100 | 250 (d99) |

| HPMC | Condux® 300 | 66 | 150 (d50) |

| HPC | CGS 50 | 100 | 53 (d50) |

| Microcrystalline cellulose | CGS 71 | 150 | 150 (d50) |