CHEmical Industry

Abrasive Polishing Agents

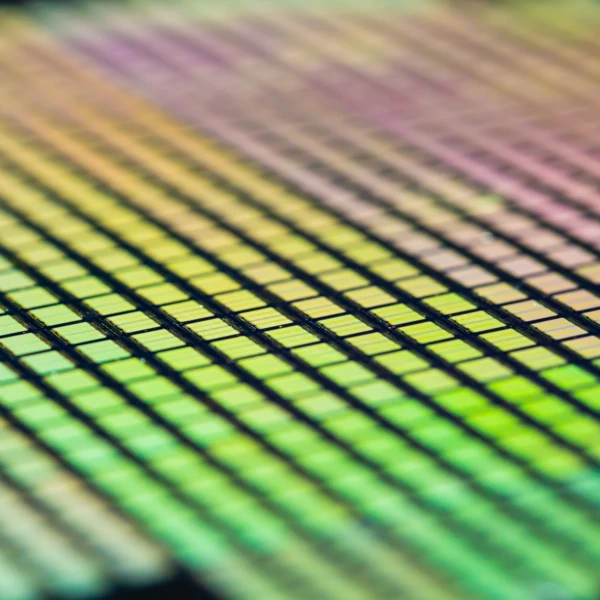

Whether for grinding, polishing or wear protection, only the hardest ceramics are used here. The most important representatives are oxides, nitrides and carbides.

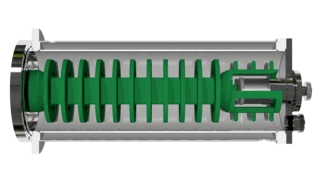

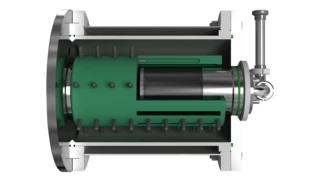

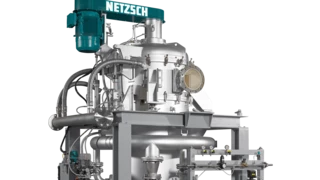

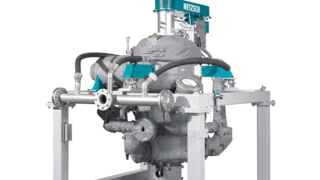

The correct choice of grinding process and grinding chamber lining are the decisive factors. For dry processing, the jet mill is particularly suitable, as the product particles grind each other.

After grinding, our high-performance classifiers ensure separation into the various FEPA classifications.

Since, in some cases, sufficiently wear-resistant grinding beads do not exist for wet mills, it is then necessary to switch to autogenic grinding with grinding grit from the corresponding regrind.