Nuestra División

NETZSCH división de Molienda & Dispersión

An Introduction to the Business Unit

Quienes somos

Las pinturas y los pigmentos hacen que la vida tenga más color, el chocolate se deshace en la boca y el maquillaje perfecto da una imagen radiante – La División de Molienda y Dispersión, una de las tres divisiones del grupo NETZSCH, ofrece un extenso programa para los diversos desafíos que plantea la ingeniería de procesos mecánicos.

Es aquí donde nos involucramos en los campos de molienda en húmedo y en seco, en la mezcla, la dispersión, la desaireación y la clasificación. La mayoría de industrias necesitan estos procesos, ya sea a nivel de laboratorio, en producción o bien plantas completas. Nuestras máquinas se usan en campos tales como la investigación nanotecnológica, en la producción de tintas, de minerales o alimentación, entre otros. La fuerza de nuestra división y nuestra diferenciación radica en la suma del know-how de proceso, en el amplio programa de maquinaria, en las soluciones aportadas a los problemas específicos de los clientes y estar presentes en todo el mundo.

Wet Grinding

NETZSCH-Feinmahltechnik leads the world in wet grinding technology. Our strength lies in the bundling of process engineering know-how with our wide range of machines, from laboratory- to productionscale machines to complete production lines. Customized for each application, wet grinding units are available for ultra-fine dispersion and grinding down into the nanometer range.

You get innovative processing systems that make it possible to manufacture your product economically with the desired characteristics. Our line of machines meets many requirements, even unusual ones. Whatever result you may need, we‘ll find a way to achieve it.

Dry Grinding

When it comes to grinding dry products, you‘ve come to the right place. From A as in activated charcoal to Z as in zirconium oxide: NETZSCH mills grind everything, with precise definition and efficiency.

With us you‘ll find a comprehensive line of mills for every fineness, all the way down into the submicron range. High-performance classifiers for the separation of ultra-fine products round out the program. We will find an economical solution for your requirements with our innovative dry grinding technology.

From the single mill to complete turnkey milling systems, we offer you non-PSR, dust explosion protected or inert gas plants, depending on your application. We match materials to the application, from stainless steel with polished surfaces to wear-protected finishes, we have the right solution for your product.

Mixing and Dispersing Technology

In mechanical process engineering, mixing and dispersing is an essential step in the process of attaining homogeneous and stable end products (suspensions and emulsions). Dispersing refers to the mixing of at least two substances that are not chemically combinable or hardly soluble. Our vast experience and competence lie primarily in dispersing solids in liquids.

For every step of the dispersing process, depending on the application, we have developed economical, eco-friendly solutions with which our customers can achieve the optimal product quality. This is particularly evident when solids are introduced into liquids. It is also true for wetting fine substances or those that are not readily wettable in water- or solvent-based systems. Our mixing, kneading and dispersing machines cover the entire spectrum of applications, from low- to high-viscosity products.

Laboratory Machines

In the area of wet and dry processing, laboratory machines for grinding, classifying, mixing, dispersing, kneading and de-aerating have become indispensable for the development of new products. This is equally true for process optimization and for processing very small quantities. Good reproducibility, high product yield and easy cleaning are the challenges to the technology. These requirements are fulfilled optimally with our flexible, easy-to-operate laboratory machines. Our laboratory program is available in all practical materials and enables a qualitative and quantitative scale-up to production machines.

Systems & Plants

In wet and dry processing, we have developed far beyond exclusive machine construction over the past few decades. At NETZSCH, machine building, systems and product know-how, process engineering, information technology and outstanding service are combined to form a whole, the system NETZSCH, which we are constantly expanding and improving.

The advantage for our customers is plant design from a single source. Wherever you work with us, your contacts are highly-qualified NETZSCH specialists. You want to enter a new market, increase your production output, have a production plant built as a turn-key project?

For all that you need a counterpart who not only knows his market but yours as well, who possesses excellent machine technology, can refer to knowledge from decades of experience, whom you don‘t have to teach the ABCs of application technology and who can economically solve new issues that arise – NETZSCH.

You decide the degree of automation, from the manually-operated production line to the fully-automatic, monitored system, any configuration is possible, in both conventional and modular design. The modular design of our plants makes it easy to expand production with a minimal space requirement, thus eliminating costly on-site installations.

From planning to commissioning and beyond, we‘ll always be at your side.

AfterSales Service

Technical assistance must arrive quickly and work perfectly. That‘s why we offer an extraordinary range of services, with the assurance that highly-qualified NETZSCH personnel perform these services all over the world. Our specialists provide quick and reliable assistance. We advise you in your own language, wherever you are.

The NETZSCH service network extends to all corners of the globe. As a result, we strengthen the competitive capacity of our customers, facilitate trouble-free, efficient processes and ensure maximum machine availability.

Our range of services includes

- Installation Support

- Spare Parts

- Field Service and Support

- Optimization Services

- NETZSCH-Beads®

NETZSCH Application Laboratories

Throughout the world – in Germany, Russia, the USA, Brazil, China and India – you have the opportunity to work with our experts in dedicated process engineering labs.

In testing, we prepare your products so as to achieve the exact result you have specified. Together with you, we carry out tests on the layout of machines, on process optimization or on quality assurance and work out process solutions. Our comprehensive analyses such as particle size distribution and viscosity as well as imaging techniques enable us to evaluate the results to the greatest extent possible.

In order to support our customers when introducing new products to the market, we also offer contract grinding on existing machines and plants.

Localizaciones

Estamos cerca de nuestros clientes

Nuestra completa red de ventas y de servicio le garantiza que Ud. disponga de soporte local efectivo y que pueda contar con un servicio post-venta directo. Al contar con plantas de producción en Alemania, Brasil, Rusia y China, cada una de ellas con programas de producción adaptados, se reducen los plazos de entrega y las rutas de transporte.

Estamos en:

- NETZSCH-Feinmahltechnik GmbH, Germany

- NETZSCH Trockenmahltechnik GmbH, Germany

- NETZSCH Vakumix GmbH, Germany

- NETZSCH Lohnmahltechnik GmbH, Germany

- NETZSCH Premier Technologies, LLC., USA

- NETZSCH Indústria e Comércio de Equipamentos de Moagem Ltda., Brazil

- NETZSCH (Shanghai) Machinery and Instruments Co., Ltd., China

- NETZSCH India Grinding & Dispersing Private Limited

- NETZSCH Mastermix Ltd., UK

- NETZSCH España S.A.U., Spain

- NETZSCH Ecutec, Spain

- AO NETZSCH Tula, Russia

- NETZSCH Makine Sanayi ve Ticaret Ltd. Sti., Izmir, Turkey

Innovation

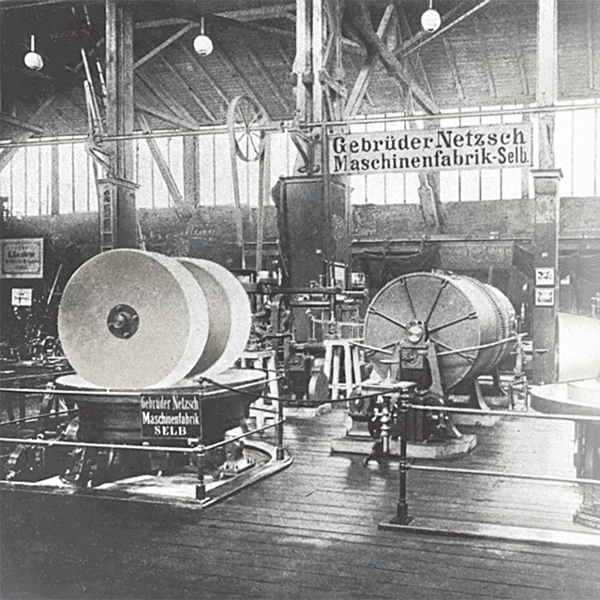

Always a step ahead – for more than 100 years

We were already building ball mills for the ceramics industry in 1896. We steadily pushed forward with the development of our technologies. For example, in the 60s we developed the first annular chamber mill with a peg/counter-peg system, the so-called John Mill, for processing printing ink.

We made rapid strides in the decades that followed: new markets emerged, and with them new developments such as the MoliNex System horizontal agitator bead mill in 1974, which was later refined to become the TriNex® System. From the house of NETZSCH also came the circulation mill, which was introduced to the market as the Zeta® System, followed by the Zeta® RS nano mill first produced in 2006.

In recent years, after the Ψ-Mix® inline mixing system, we have introduced the innovative s-Jet® process for dry grinding and the revolutionary Omega economic dispersionizer.

The basis for our new developments is our experience from over a century of processing technology, our pool of knowledge about process and applications technology and the trusting cooperation with our customers from many sectors of industry. Our ambition to be able to offer our customers the optimal solution for their applications remains undiminished.

Aplicaciones

Su aplicación - Nuestra razón de ser

Usted es nuestra razón de ser – el diseño y la construcción de nuestras máquinas está totalmente orientado a sus deseos e ideas, con la flexibilidad que le puede ofrecer una empresa de tamaño medio que tiene siempre en mente al cliente.

Hace más de 50 años que entramos en el mundo de la molienda y la mezcla. Esto nos da la seguridad y la confianza para, conjuntamente con Usted, encontrar la mejor solución posible a su aplicación y proyecto.

- Investigación & Desarrollo, Enseñanza

- Minerales / Metales

- Pintura

- Pigmentos / Colorantes

- Tintas de impresión

- Ciencias de la vida

- Alimentación

- Confectionery

- Cerámica / Vidrio

- Agroquímica

- Aplicaciones Nano

- Adhesivos / Sellantes

- Celulosa / Pasta